Charofire -

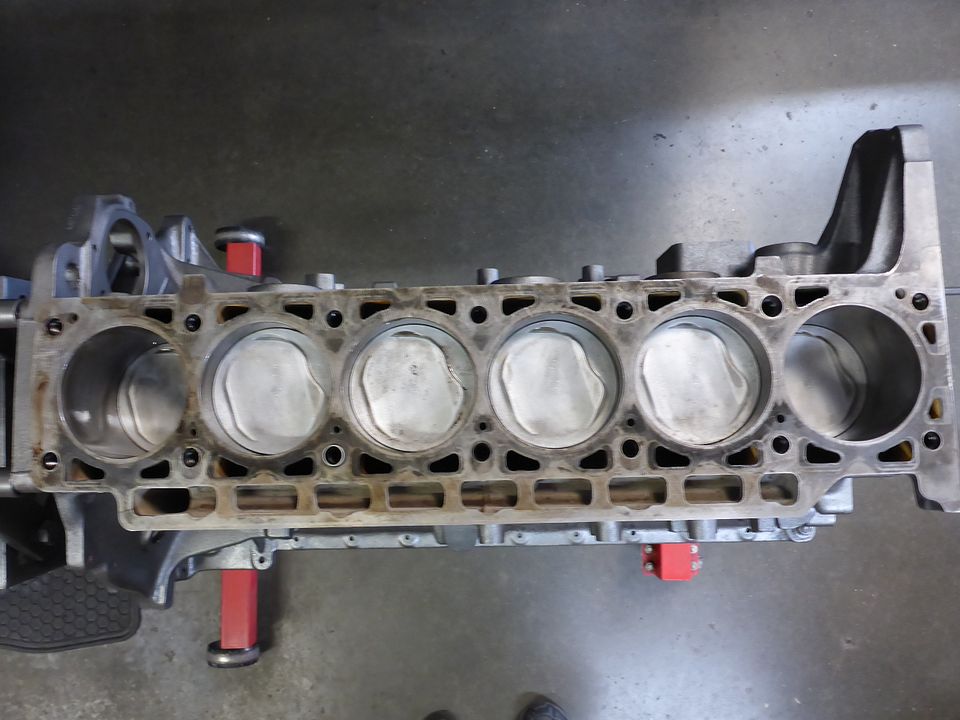

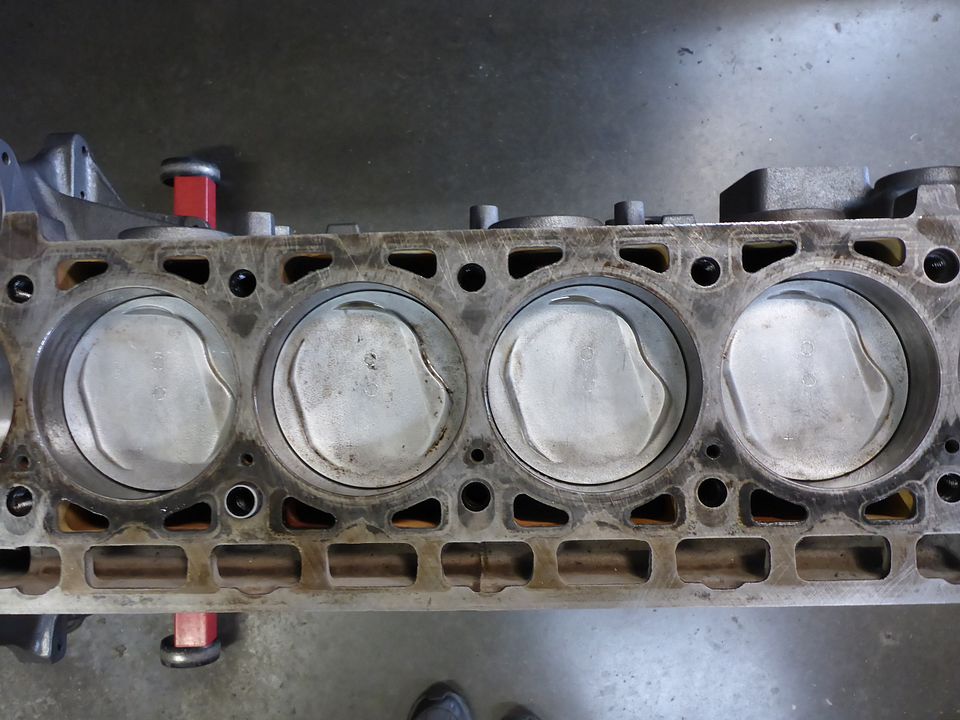

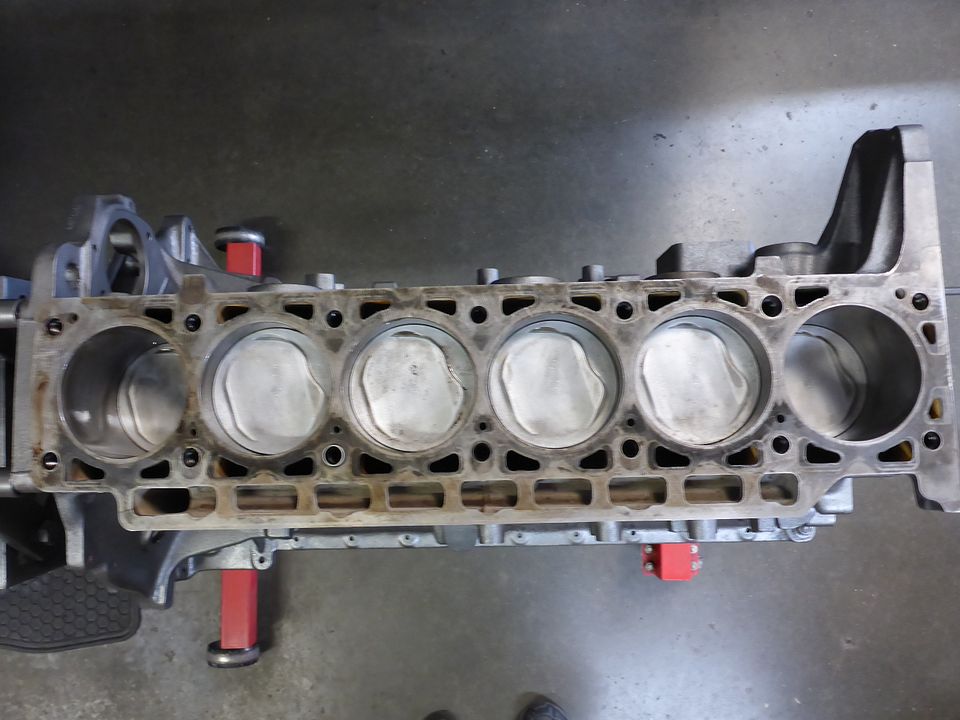

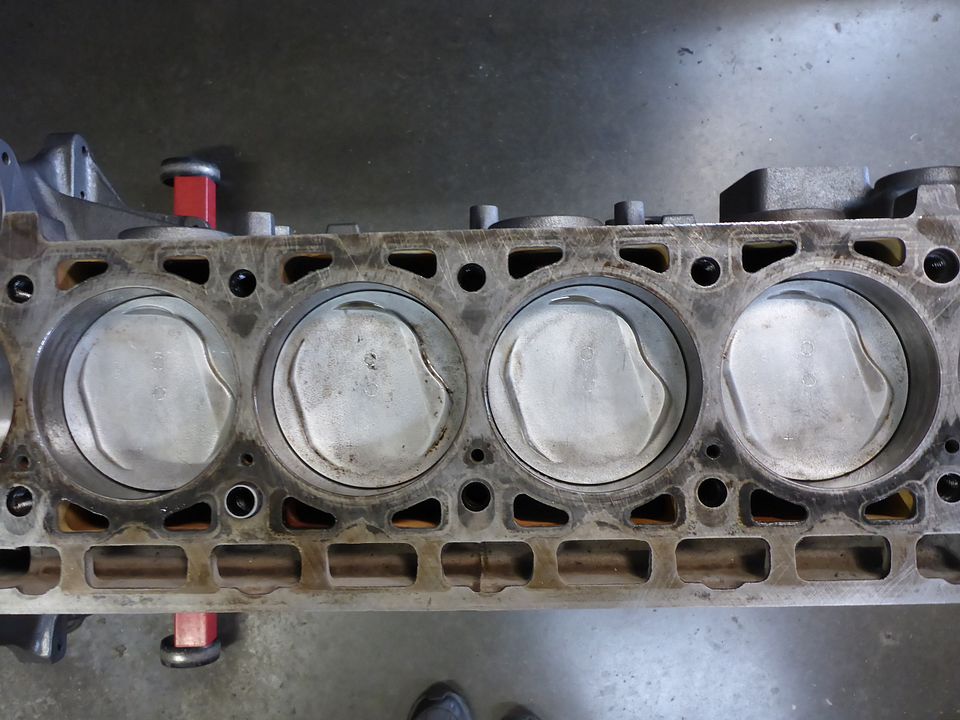

I recently had a M30B35 from a '90 535i. Block was set out to a machine shop, dis-assembled, HOT TANKED, inspected. Block measured Standard size - MAIN bearings, Rod bearings, rings. Cylinder Head was dis-assembled, pressure tested and checked for pin holes & cracks.

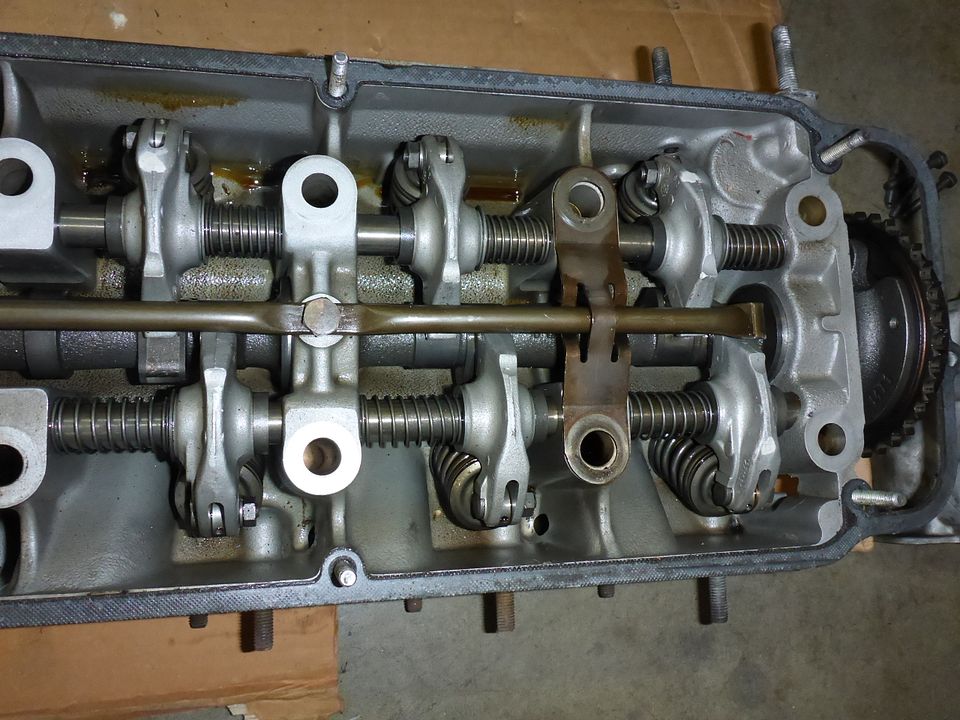

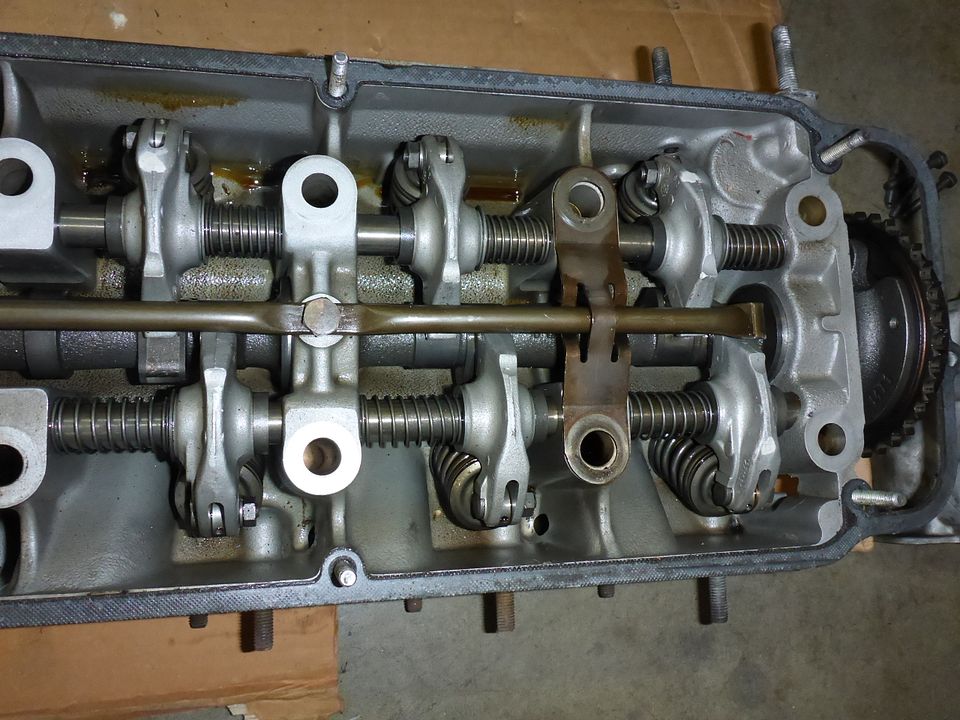

Large wear marks are evident (virgin head). Shows it was not decked.

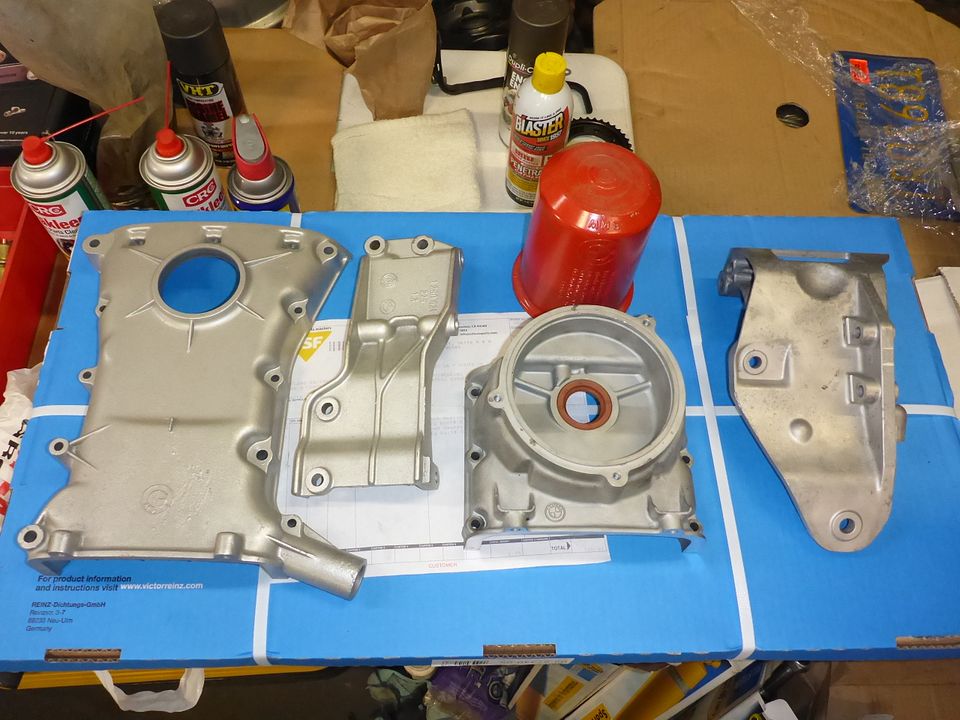

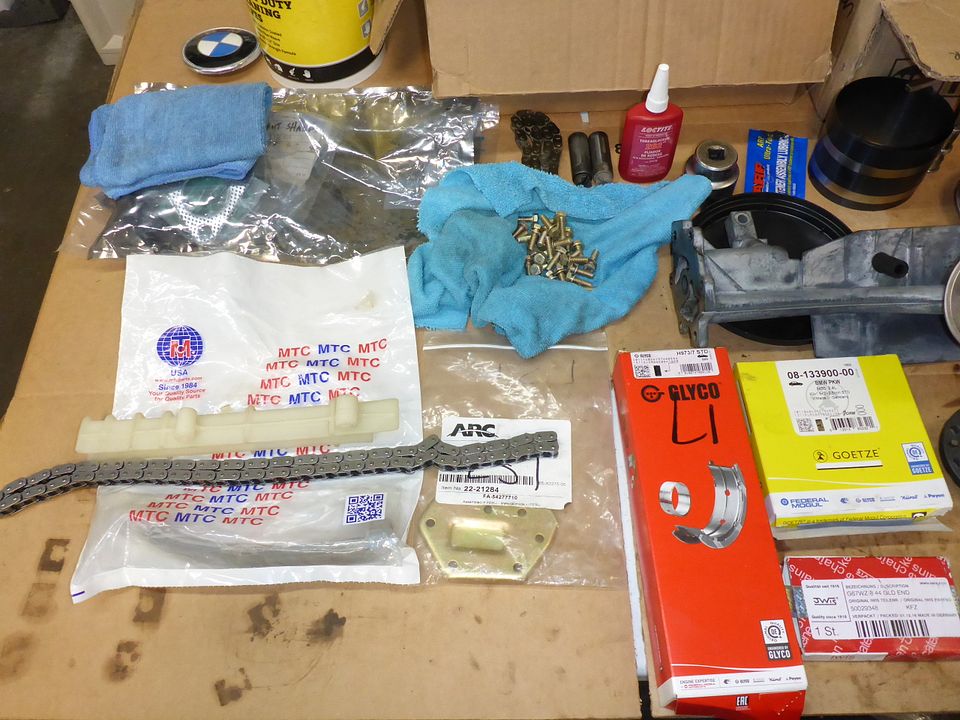

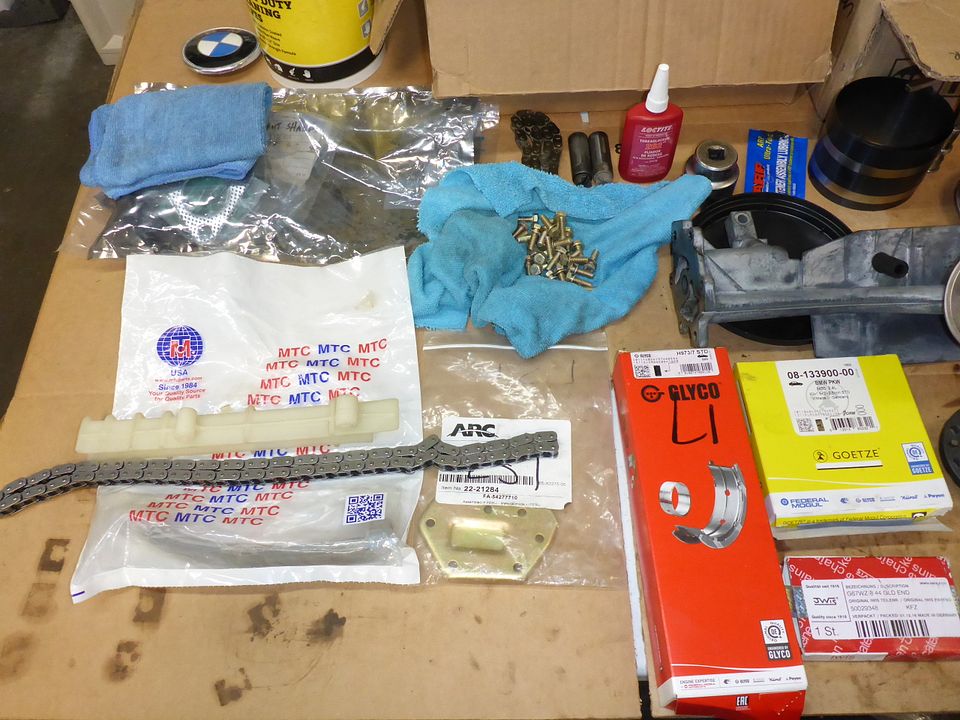

Provided all internal OE parts for my Engine Builder: Black VHT paint for the Block. Alumi-Blast for all the aluminum external parts.

NEW freeze plugs, Glyco main bearings, Glyco rod bearings, BMW OE bronze bushings (RODS were re-sized), Gotze ring set. eLring gasket set.

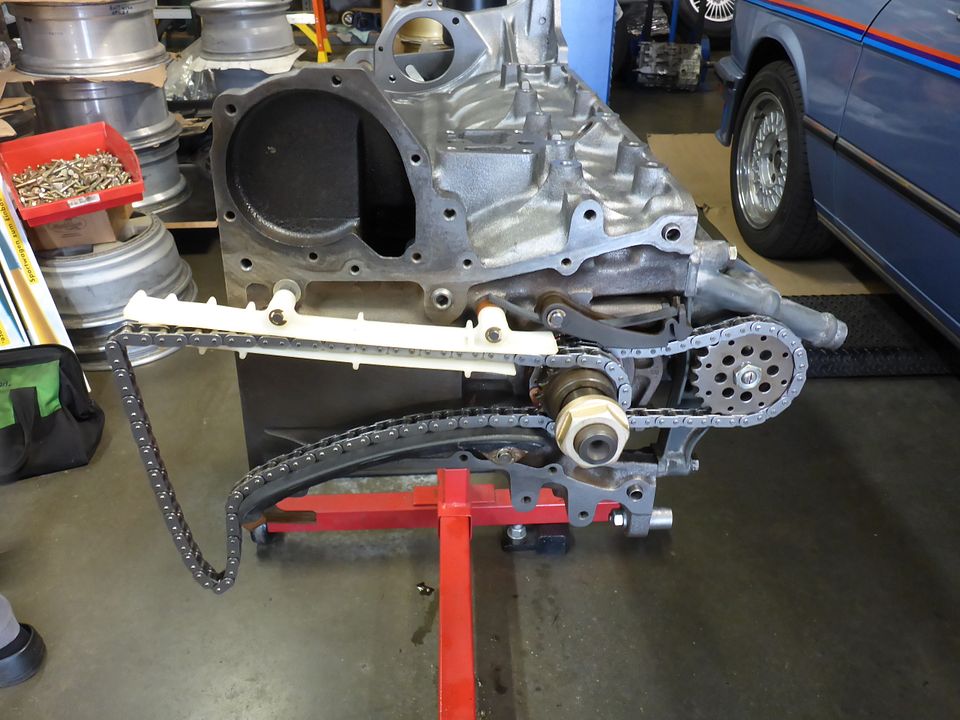

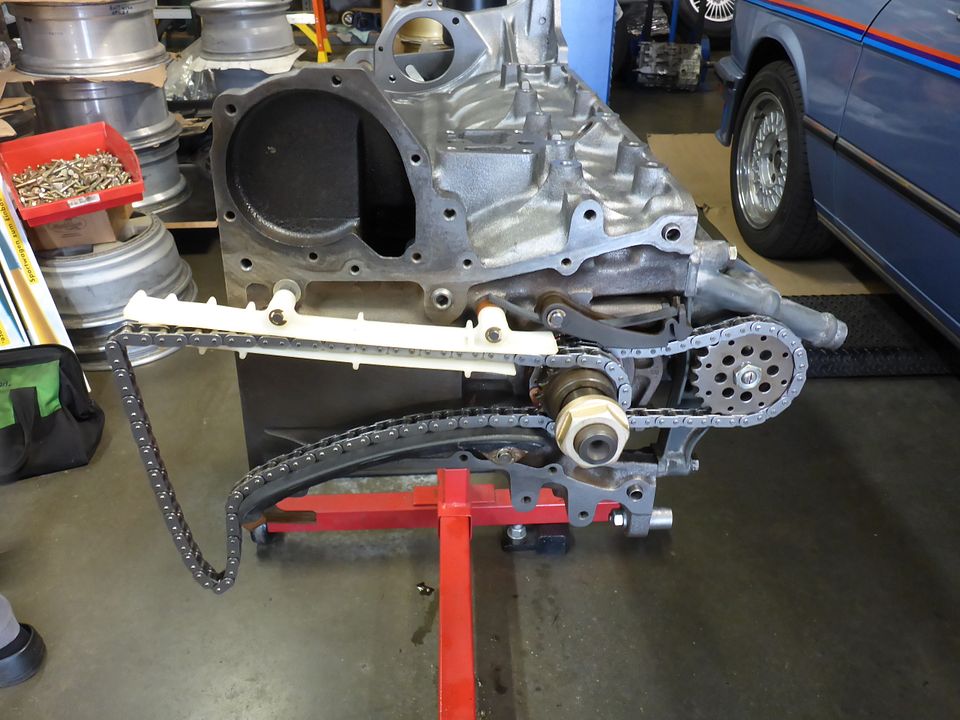

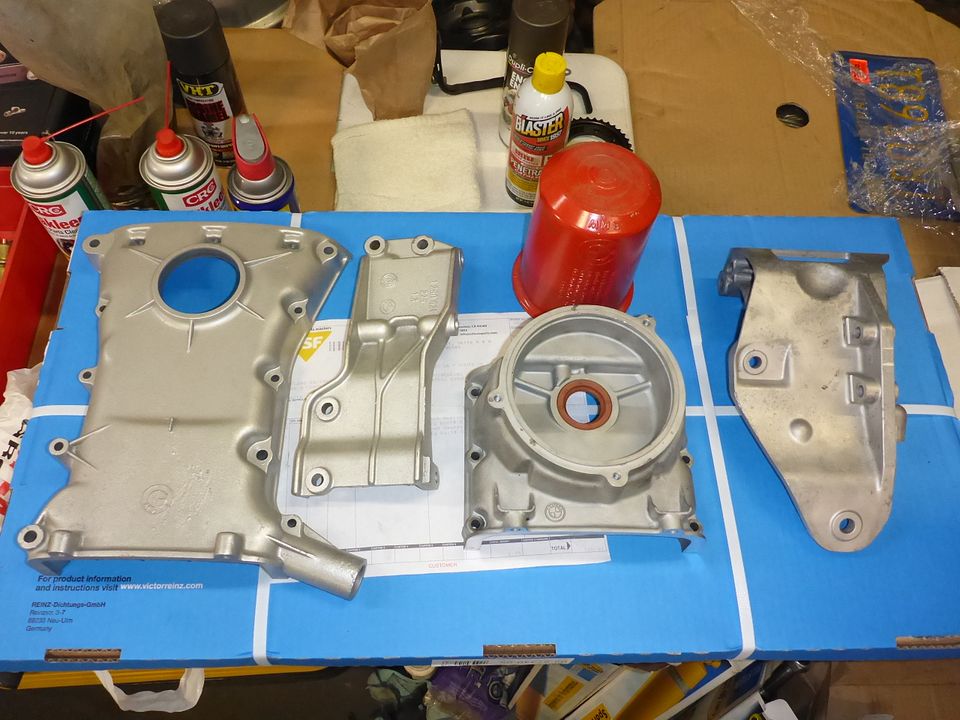

Oil pump checked - New oil pump chain, tensioner. Main front chain, tensioner, tensioner piston & spring. 9:1:1 compression - 210H.P./225 ft. lbs torque

3 angle valve job, new seals, banjo bolts/crush washers (always) for the spray bar.

All hardware was GOLD ZINC plated.

RC Engineering balanced & blueprinted injectors.

New water pump Thermostat housing

Correct TPS

Harmonic balancer

B35 crank position sensor/bracket

B35 throttle switch

CUSTOM 1.3 wiring harness with e28 fuse plug connector (wired)

#179 ECU 1.3 Motronic

B35 Intake manifold (Larger diameter) better flow.