LSD Rebuild Info

Posted: Jan 10, 2013 9:05 AM

I posted this on someones LSD inquiry. I thought I would put it here too. These are other sites were they have rebuilt a LSD.

I know you can buy a used one for about $250-$350 but if you want to tackle a rebuild and don't want to pay Metric Mechanic or Diffs Online $1200 to do it. Here you go.

You can still buy all of the bearings, clutch plates, and seals for the medium case diff.

Rmeuropean.com has the parts listed for pretty good prices.

ie - bearing is $21

http://www.rmeuropean.com/Part-Number/C ... 21741.aspx

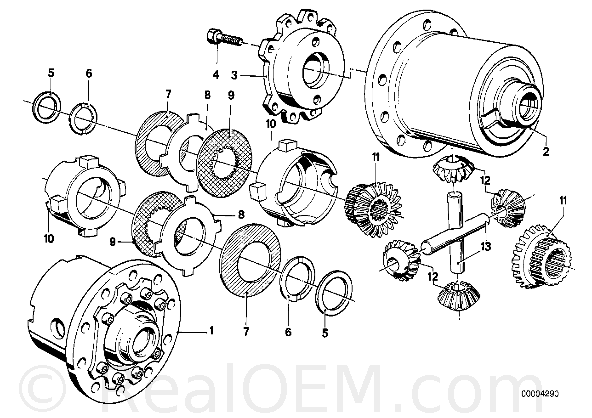

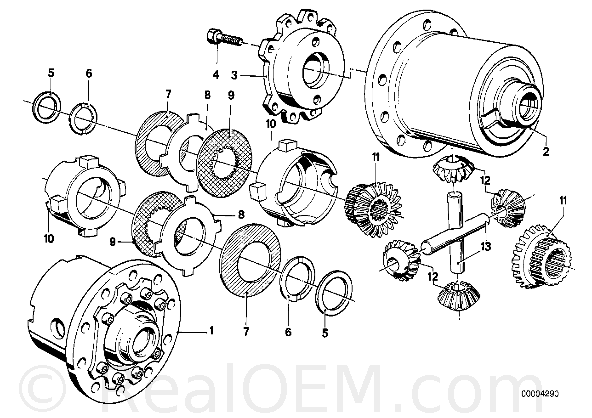

Your local dealer can also get them for big bucks. If you look them up on realoem.com make sure you look them up for a 87 e24 (635i) they part the diff better on that car for some reason.

http://www.realoem.com/bmw/showparts.do ... g=33&fg=15

Pretty sure medium case has 188mm internals which are the same on alot including the e36

Hear are some sites for diff rebuilds DIYs:

http://www.ohiobimmers.com/forum/showthread.php?t=3624 The Best one , but you have to login

Pretty Good tear down and rebuild: (check out this M3 rebuild, AMAZING!!)

http://www.r3vlimited.com/board/showpos ... stcount=44

http://www.r3vlimited.com/board/showpos ... stcount=45

http://www.r3vlimited.com/board/showpos ... stcount=46

http://www.r3vlimited.com/board/showthread.php?t=92714

http://www.m3forum.net/m3forum/showthread.php?t=362856

http://forums.bimmerforums.com/forum/sh ... ?t=1650106

Here are some important specs for E36 188mm differentials (others similar):

Ring and Pinion Backlash = 0.06mm to 0.14mm (0.0024in to 0.0055in - Metric Mechanic believes ideal backlash is 0.003in to 0.0035in, which falls well within the BMW TIS limits)

Pinion Preload = ~12in-lbs to 23in-lbs according to TIS (Metric Mechanic claims 14in-lbs to 16in-lbs)

Carrier Preload = ~11in-lbs to 23in-lbs according to TIS (Metric Mechanic claims 9in-lbs to 11in-lbs)

Axle Cap Bolts = 10ft-lbs + 40 degrees angle torque (with Loctite 242)

Rear Cover Bolts = 34ft-lbs

Limited Slip Carrier Cover Bolts = 25ft-lbs

Ring Gear Bolts = 110ft-lbs (with Loctite 271)

Part Numbers:

**Asterik denotes a non-BMW part number. It is specific to the part in general, but not brand, e.g. Timken HM88542 or SKF HM88542. Once you have the bearing and race part numbers, the sky is the limit. I refuse to pay $73 per bearing through the stealership for an SKF bearing, the same one I can find for $22 with the generic number.

**HM88510 Pinion Race x1 **

**HM88542 Pinion Bearing x1 **

**LM503310 Carrier Race x2 **

**LM503349A Carrier Bearing x2 **

**HM89410 Pinion Race x1 **

**HM89449 Pinion Bearing x1 **

33107505602 Axle Shaft Seal x2

33111214144 Axle Cap O-Ring x2

33139065734 or 33139065735 Shim Sets for Carrier

33101214099 Pinion Shaft Seal x1

33121744368 Pinion Crush Sleeve x? (Depends how experienced you are. If you've done it before, you can suffice with one. If not, I'd have at least two on hand.)

33129065179 or 33129065180 Shim Sets for Pinion

23211490120 Securing Plate for Pinion Nut x1

33121200258 Pinion Collar Nut x1

Brands for roller bearings and races:

Timken

SKF

FAG

National

BCA

Fafnir

Koyo

Tools Needed:

Shop press

Race/Seal driver kit

Dial indicator with clamp or magnetic base

MAPP gas torch

Small cut-off wheel (air powered)

Bearing puller

Metric sockets up to 30mm

Ratchet

Impact

Assortment of screwdrivers

A few punches and chisels

Hammer

Large brass drift

I'm putting this out here as a feeler so that more people have an understanding of what goes into building a diff, and that IT IS POSSIBLE TO BUILD ONE

_________________

I know you can buy a used one for about $250-$350 but if you want to tackle a rebuild and don't want to pay Metric Mechanic or Diffs Online $1200 to do it. Here you go.

You can still buy all of the bearings, clutch plates, and seals for the medium case diff.

Rmeuropean.com has the parts listed for pretty good prices.

ie - bearing is $21

http://www.rmeuropean.com/Part-Number/C ... 21741.aspx

Your local dealer can also get them for big bucks. If you look them up on realoem.com make sure you look them up for a 87 e24 (635i) they part the diff better on that car for some reason.

http://www.realoem.com/bmw/showparts.do ... g=33&fg=15

Pretty sure medium case has 188mm internals which are the same on alot including the e36

Hear are some sites for diff rebuilds DIYs:

http://www.ohiobimmers.com/forum/showthread.php?t=3624 The Best one , but you have to login

Pretty Good tear down and rebuild: (check out this M3 rebuild, AMAZING!!)

http://www.r3vlimited.com/board/showpos ... stcount=44

http://www.r3vlimited.com/board/showpos ... stcount=45

http://www.r3vlimited.com/board/showpos ... stcount=46

http://www.r3vlimited.com/board/showthread.php?t=92714

http://www.m3forum.net/m3forum/showthread.php?t=362856

http://forums.bimmerforums.com/forum/sh ... ?t=1650106

Here are some important specs for E36 188mm differentials (others similar):

Ring and Pinion Backlash = 0.06mm to 0.14mm (0.0024in to 0.0055in - Metric Mechanic believes ideal backlash is 0.003in to 0.0035in, which falls well within the BMW TIS limits)

Pinion Preload = ~12in-lbs to 23in-lbs according to TIS (Metric Mechanic claims 14in-lbs to 16in-lbs)

Carrier Preload = ~11in-lbs to 23in-lbs according to TIS (Metric Mechanic claims 9in-lbs to 11in-lbs)

Axle Cap Bolts = 10ft-lbs + 40 degrees angle torque (with Loctite 242)

Rear Cover Bolts = 34ft-lbs

Limited Slip Carrier Cover Bolts = 25ft-lbs

Ring Gear Bolts = 110ft-lbs (with Loctite 271)

Part Numbers:

**Asterik denotes a non-BMW part number. It is specific to the part in general, but not brand, e.g. Timken HM88542 or SKF HM88542. Once you have the bearing and race part numbers, the sky is the limit. I refuse to pay $73 per bearing through the stealership for an SKF bearing, the same one I can find for $22 with the generic number.

**HM88510 Pinion Race x1 **

**HM88542 Pinion Bearing x1 **

**LM503310 Carrier Race x2 **

**LM503349A Carrier Bearing x2 **

**HM89410 Pinion Race x1 **

**HM89449 Pinion Bearing x1 **

33107505602 Axle Shaft Seal x2

33111214144 Axle Cap O-Ring x2

33139065734 or 33139065735 Shim Sets for Carrier

33101214099 Pinion Shaft Seal x1

33121744368 Pinion Crush Sleeve x? (Depends how experienced you are. If you've done it before, you can suffice with one. If not, I'd have at least two on hand.)

33129065179 or 33129065180 Shim Sets for Pinion

23211490120 Securing Plate for Pinion Nut x1

33121200258 Pinion Collar Nut x1

Brands for roller bearings and races:

Timken

SKF

FAG

National

BCA

Fafnir

Koyo

Tools Needed:

Shop press

Race/Seal driver kit

Dial indicator with clamp or magnetic base

MAPP gas torch

Small cut-off wheel (air powered)

Bearing puller

Metric sockets up to 30mm

Ratchet

Impact

Assortment of screwdrivers

A few punches and chisels

Hammer

Large brass drift

I'm putting this out here as a feeler so that more people have an understanding of what goes into building a diff, and that IT IS POSSIBLE TO BUILD ONE

_________________