Page 13 of 15

Posted: Mar 03, 2012 1:53 PM

by grey ghost

Blew it up. Hg is toast. Leaking coolant on the exhaust side.

Too much boost.

I'll be pulling and replacing the head in the next week or so.

Shit happens.

Posted: Mar 03, 2012 1:58 PM

by Nebraska_e28

how much boost? Or was it detonation? Been running 7.5 - 10psi on bone stock motor now with 220k & MS2 for two years now & not a single problem. Sucks to hear man.

Posted: Mar 03, 2012 2:08 PM

by grey ghost

Nebraska_e28 wrote:

how much boost? Or was it detonation? Been running 7.5 - 10psi on bone stock motor now with 220k & MS2 for two years now & not a single problem. Sucks to hear man.

Like 17psi. I know, way too much.

But I've been having fuel pressure issues so I think it was a deadly combo of detonation due to lean conditions and too much boost.

It was cool when it held 10psi all the way to 6k in 2nd, 3rd, 4th and as much of 5th as the road would allow.

But I got greedy and wanted more.

Oh well, at least I had fun.

Posted: Mar 03, 2012 2:18 PM

by Ken H.

grey ghost wrote:Blew it up. Hg is toast. Leaking coolant on the exhaust side.

Too much boost.

I'll be pulling and replacing the head in the next week or so.

Shit happens.

BTDT. A true piss-cutter. Couple of suggestions.

1. Using a machinist's straight edge, check to be sure that there wasn't any head distortion or warpage. Bad berries if there was.

2. Replace stock HG with a Cometic MLS unit.

3. Replace the head bolts. All of them. Spend a few $$ and get a set of ARP head studs. Follow their instructions for installation.

4. Get access to a calibrated MAP gauge when you begin to dial things in. Not unheard-of that an off-the-shelf boost gauge is in error.

K27 @ 10 psi is moving how much air mass--poundage? You may be running the compressor into choke, aggravating a lot of your problems.

Posted: Mar 03, 2012 2:27 PM

by grey ghost

Ken H. wrote:grey ghost wrote:Blew it up. Hg is toast. Leaking coolant on the exhaust side.

Too much boost.

I'll be pulling and replacing the head in the next week or so.

Shit happens.

BTDT. A true piss-cutter. Couple of suggestions.

1. Using a machinist's straight edge, check to be sure that there wasn't any head distortion or warpage. Bad berries if there was.

2. Replace stock HG with a Cometic MLS unit.

3. Replace the head bolts. All of them. Spend a few $$ and get a set of ARP head studs. Follow their instructions for installation.

4. Get access to a calibrated MAP gauge when you begin to dial things in. Not unheard-of that an off-the-shelf boost gauge is in error.

K27 @ 10 psi is moving how much air mass--poundage? You may be running the compressor into choke, aggravating a lot of your problems.

I have ARP head studs in there now. Can I reuses them?

I have a good replacement head to go on.

It held 10psi when I bolted it on, thats what the m102 pushed stock, I added a little, well a lot, and killed it.

Posted: Mar 03, 2012 2:30 PM

by Nebraska_e28

grey ghost wrote:

But I got greedy and wanted more.

.

Welcome to the dark side!

Posted: Mar 03, 2012 2:43 PM

by grey ghost

Nebraska_e28 wrote:grey ghost wrote:

But I got greedy and wanted more.

.

Welcome to the dark side!

Luke, I am your father.

Posted: Mar 03, 2012 4:19 PM

by Ken H.

Nicely put, LJ.

ghost, I'm sorry, but you, Sir, were waaaay out of line. 17 psi thru a K27?? MmmmmmmNo. Don't think so. Take a look on a compressor map.

The ARP studs may be OK, but I wouldn't trust them. Nothing to do with their quality, but there has undoubtedly some stretching when the HG let go.

Do yourself a favor and use a Cometic MLS gasket on the rebuild.

IMO, if you want to keep using the K27 and the M102, you need to be happy at ~8-10 psi.

If you want to try for more, I think you're looking towards a TCD setup.

FI is a very slippery slope.

Posted: Mar 03, 2012 4:34 PM

by grey ghost

Ken H. wrote:Nicely put, LJ.

ghost, I'm sorry, but you, Sir, were waaaay out of line. 17 psi thru a K27?? MmmmmmmNo. Don't think so. Take a look on a compressor map.

The ARP studs may be OK, but I wouldn't trust them. Nothing to do with their quality, but there has undoubtedly some stretching when the HG let go.

Do yourself a favor and use a Cometic MLS gasket on the rebuild.

IMO, if you want to keep using the K27 and the M102, you need to be happy at ~8-10 psi.

If you want to try for more, I think you're looking towards a TCD setup.

FI is a very slippery slope.

Yeah. I admit it, me and greed did it in. But it was fun while it lasted. I'll be going back to 10psi as it was before and as it was meant to be.

Funny thing is that it starts right up. I can tell by the way it idles that something is up.

Yesterday the 1st start clear steam never went away, today there is none.

Posted: Mar 03, 2012 6:39 PM

by Nebraska_e28

Ken H. wrote: IMO, if you want to keep using the K27 and the M102, you need to be happy at ~8-10 psi.

.

/\ what he said + look at what you can do to lower your charge temps, that will be key

Posted: Mar 03, 2012 9:49 PM

by Shadow

Ken H. wrote:

The ARP studs may be OK, but I wouldn't trust them. Nothing to do with their quality, but there has undoubtedly some stretching when the HG let go.

Is ARP head stud kit #201-4602 for bmw 535, 635 and 735 the right application for the m30b35? That was what I had in there, and they aren't shouldered like the stock head bolts to locate the rocker shafts. With the ARP studs, the rocker shafts had lateral play, noticeable at the cam eccentric. The stock head bolt is 1.1cm, then shoulders to over 1.2cm. The ARP studs measure just under 1cm all the way to the threads.

http://www.mye28.com/viewtopic.php?p=98 ... ht=#988168

http://www.mye28.com/viewtopic.php?p=98 ... ht=#988168

This has got me worried too.

20psi and the stock bolts are doing me fine.

Posted: Mar 06, 2012 5:11 PM

by grey ghost

So I'll be pulling the head tomorrow.

Dropping at the machine shop to have it pressure tested, checked for cracks and resurfaced.

The sting has worn off, but I'm sure it will be back when the tear-down starts......

Pulling a head is a royal PITA, and putting it back is even worse....

Posted: Mar 06, 2012 6:17 PM

by turbodan

I wouldn't bother with a pressure test. If it cracked you would have oil in the coolant. Just have them resurface it.

Theres nothing wrong with running 17 psi. You just can't do it with a K27. Not all turbos are the same. Nowhere near it.

Posted: Mar 06, 2012 6:59 PM

by grey ghost

turbodan wrote:I wouldn't bother with a pressure test. If it cracked you would have oil in the coolant. Just have them resurface it.

Theres nothing wrong with running 17 psi. You just can't do it with a K27. Not all turbos are the same. Nowhere near it.

I've not done anything yet as all the tools I need are in my storage unit.

I just went out again to check for oil in the coolant, again, and found none.

I need to go get my compression tools so I can figure out were the blowout is, so I know were to look when I pull the head.

The old girl still starts right up and idles. Just now, it idled like nothing was wrong...

Upper hose was still hard from two days ago. That means what, waterpump or thermo, or both.

Posted: Mar 06, 2012 7:05 PM

by marc79euro645

I just reviewed a couple datalogs for my m106/745/k27.

The best run of 4 on new laptop I found I made 18.7# boost,, Manifold air temps was 95f,under max boost 102f, shortly after climbed to 121.4f then quickly dropped back to 95f. This is with a small 745 i/c in the front corner.. I blew 6 head gaskets in 6 months, man I've got that job down pat! The key to my current builds' survival has been the tune.

Timing down to 10* @ max boost,55# injectors and megasquirt2 to control both.

Just sayin, k27 is not a bad turbo

marc

Posted: Mar 06, 2012 7:13 PM

by Frybrid 524td

grey ghost wrote:Upper [radiator] hose was still hard from two days ago. That means what[?]

Exhaust gases are leaking into your cooling system and over-pressurizing it.

Posted: Mar 06, 2012 7:19 PM

by grey ghost

Frybrid 524td wrote:grey ghost wrote:Upper [radiator] hose was still hard from two days ago. That means what[?]

Exhaust gases are leaking into your cooling system and over-pressurizing it.

OK, hg for sure. you can see how I'm reaching for light hoping not to have to do this again, but I guess it has to come off.....

Posted: Mar 06, 2012 9:24 PM

by turbodan

grey ghost wrote:turbodan wrote:I wouldn't bother with a pressure test. If it cracked you would have (correction) coolant in the oil. Just have them resurface it.

Theres nothing wrong with running 17 psi. You just can't do it with a K27. Not all turbos are the same. Nowhere near it.

I've not done anything yet as all the tools I need are in my storage unit.

I just went out again to check for oil in the coolant, again, and found none.

I need to go get my compression tools so I can figure out were the blowout is, so I know were to look when I pull the head.

The old girl still starts right up and idles. Just now, it idled like nothing was wrong...

Upper hose was still hard from two days ago. That means what, waterpump or thermo, or both.

I actually should have said coolant in the oil. I misspoke. Oil in the coolant is quite rare.

Posted: Mar 07, 2012 4:36 PM

by grey ghost

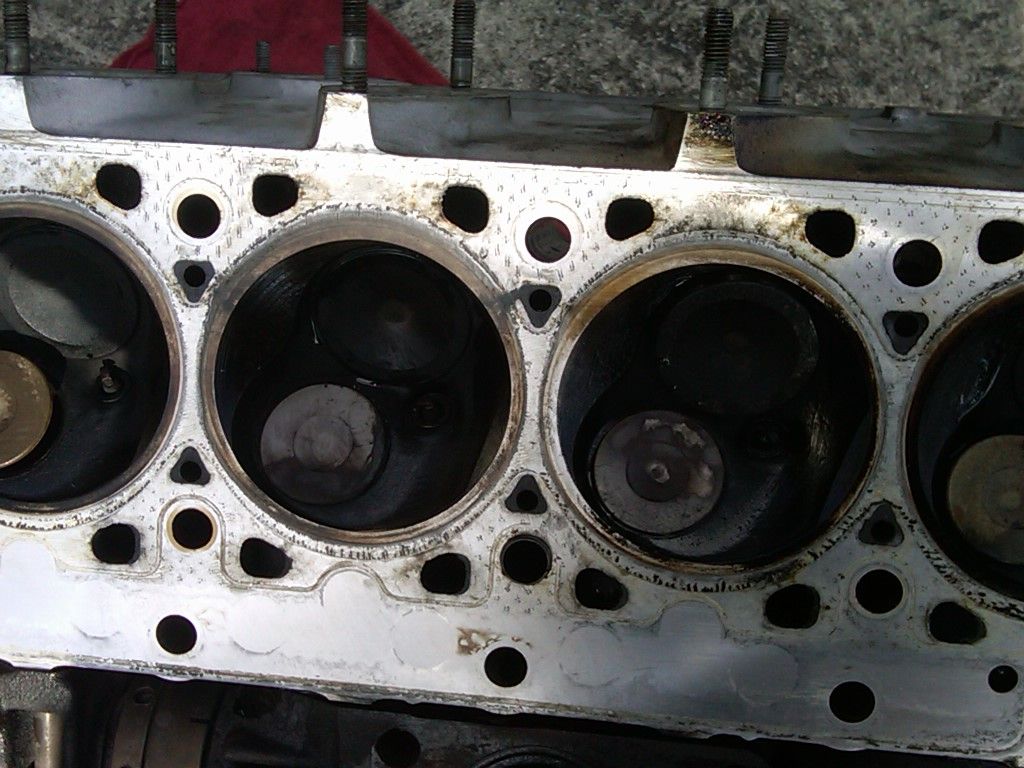

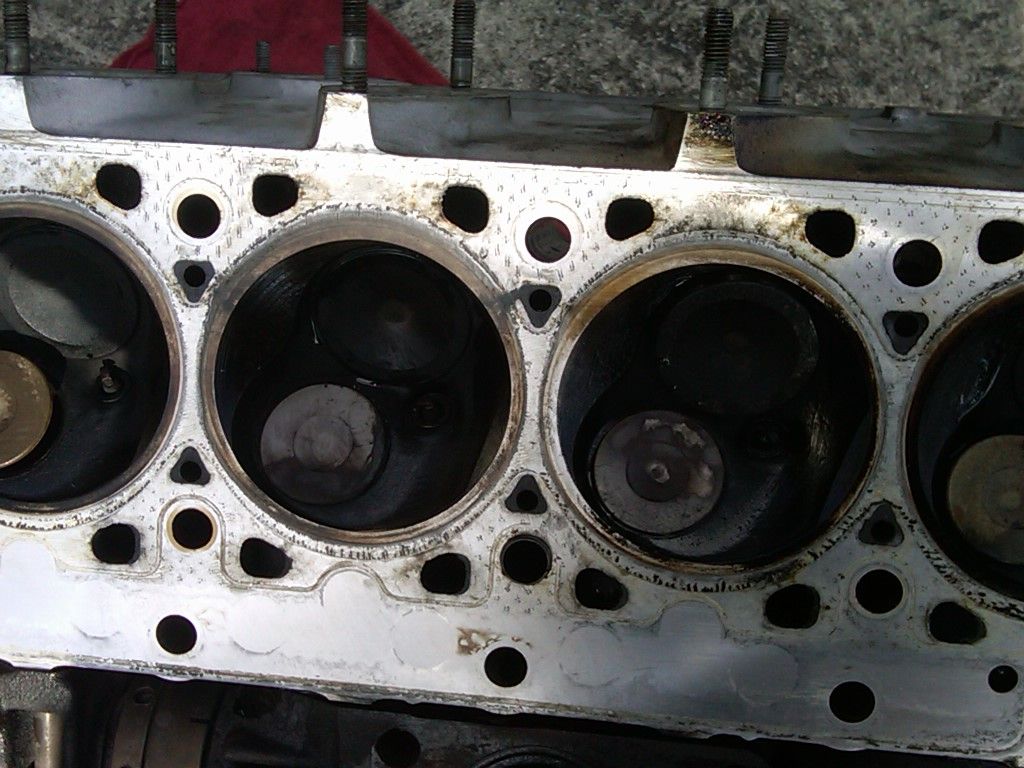

Head is off.

Coolant leak into cylinder #4.

I could see that some of the other coolant ports were on the way out.

While the right side had breached, the left side was not too far behind.

So the head is off and the shop is expecting it on Friday.

I'll be bringing a replacement head just in case this one is too far gone, although I doubt it.

Any thoughts.

Posted: Mar 07, 2012 4:42 PM

by Coldswede

I bet you will be okay, the carbon wasn't even all steam cleaned out of the combustion chambers.

New head bolts called for though. Hope it works out well.

Posted: Mar 07, 2012 4:44 PM

by grey ghost

Coldswede wrote:I bet you will be okay, the carbon wasn't even all steam cleaned out of the combustion chambers.

New head bolts called for though. Hope it works out well.

I need new head bolts even if I'm running ARPs?

Posted: Mar 07, 2012 4:58 PM

by Coldswede

Oops missed that part.

I would think the studs would be okay, I'd defer that to the real experts here.

Posted: Mar 07, 2012 5:24 PM

by turbodan

I've reused Raceware studs many times, even after blown HG's. I have noticed that the gasket itself always deforms with studs. That indicates to me that the seal between the gasket and mating surfaces is holding but the gasket itself can't support the pressure. If the studs were stretching I would expect the pressure to simply blow by the gasket like it does with the stock head bolts under boost.

Posted: Mar 09, 2012 3:24 PM

by grey ghost

Head is cracked for sure, I found the crack when loading it into the car this morning.

I pointed it out to the machinist and he said "game over"

I should have taken a picture but I didn't.

Luckily I had the replacement head with me.

So it will go into the hot tank, be pressure checked, resurfaced and install in the next few days.....

Posted: Mar 09, 2012 4:19 PM

by turbodan

Are you sure? Any pics? Where is the suspected crack located?

Posted: Mar 09, 2012 4:29 PM

by Duke

turbodan wrote:Are you sure? Any pics? Where is the suspected crack located?

grey ghost wrote:I should have taken a picture but I didn't.

RTFP

Posted: Mar 09, 2012 5:39 PM

by grey ghost

Duke wrote:turbodan wrote:Are you sure? Any pics? Where is the suspected crack located?

grey ghost wrote:I should have taken a picture but I didn't.

RTFP

?RTFP

The crack was not suspected, it was quite clear.

It was about 1/2 to the cylinder dome, or valves of #1 and ran to the edge and down the side of the head about 1.5".

But I don't have any pictures.....

Here is were the crack was located, my recreation.

It didn't run thru any of the ports though, at least on visual inspection....

Posted: Mar 15, 2012 5:34 PM

by grey ghost

Got my head back today. I may start the install tomorrow.

Here are a few pictures of the cracked head.

Posted: Mar 15, 2012 5:41 PM

by cvillebimmer

Damn, you rocked that bad boy!

Posted: Mar 15, 2012 6:10 PM

by grey ghost

cvillebimmer wrote:Damn, you rocked that bad boy!

Yup. I drive for fun. No pussy footing around.

But of course, I pay the price as well.

Putting the head on is easy NOW with all the practice I've had.

Its just that one nut on the bottom of the intake near the fire wall. SOB

Anyone have any tricks?