Whatever happened to that BMW anyway? Last I saw on here was that it was sold to TT et'al. Does it run now? Anybody driving it?RossDinan6 wrote:It will be interesting watching this thing implode like the BMW.

Ross

External links now open in a new browser tab - turn this off in your UCP - Read more here.

OPERATION TIGER'S TEETH -**Boltin on MO Power**

Last I heard from Tony was that it is running fine but is in storage due to the economy (whatever that means). I told him I would buy it back when they need space.L_N_Love wrote:Whatever happened to that BMW anyway? Last I saw on here was that it was sold to TT et'al. Does it run now? Anybody driving it?

-

Alfonso Bedoya

- Posts: 1326

- Joined: Sep 16, 2010 3:15 PM

- Location: Van Isle, B.C. Canada

-

yomenendez

- Posts: 164

- Joined: Jan 23, 2010 9:37 PM

- Location: Central Florida

The tiger

Take it easy on the m20 eta....we are a sensitive bunch of 5'ers...our truck engine will outlast all of you.....

Yo

Yo

Wish you would.Duke wrote:Last I heard from Tony was that it is running fine but is in storage due to the economy (whatever that means). I told him I would buy it back when they need space.L_N_Love wrote:Whatever happened to that BMW anyway? Last I saw on here was that it was sold to TT et'al. Does it run now? Anybody driving it?

-

Rich Euro M5

- Posts: 6098

- Joined: Mar 10, 2006 6:20 AM

- Location: Klein, Texas

You do know that Tony doesn't actually own Duke's M535i? TT works with some guy with deep pockets who collects interesting cars for resale.L_N_Love wrote:Whatever happened to that BMW anyway? Last I saw on here was that it was sold to TT et'al. Does it run now? Anybody driving it?RossDinan6 wrote:It will be interesting watching this thing implode like the BMW.

Ross

Economy sucks, particularly in AZ, therefore the owner of Duke's M535i is sitting it out, hoping the market improves.Duke wrote:Last I heard from Tony was that it is running fine but is in storage due to the economy (whatever that means).

Rich

Started the spring mount reinforcement yesterday.

The front spring mount is a natural “hinge” in the chassis structure where the rear sub frame joins the body tub and X member. Most if not all Tigers have cracks there and it is only made worse with more HP.

30 minutes work and the rear axle is easily out.

This is the left side that I have not touched yet. Looks OK but will know for sure once I start cleaning the area up.

Right side after lots of scraping, wire brush, grinder...etc. Still needs more prep. There are indications of welding to the left of the mount.

The reinforce plates. You can see the plates for the right side that I have been shaping and grinding to fit.

A friend of mine will bring his MIG rig over this weekend and then we will get everything welded in.

More to follow.

While I am at it, I am going to install a drive shaft loop.

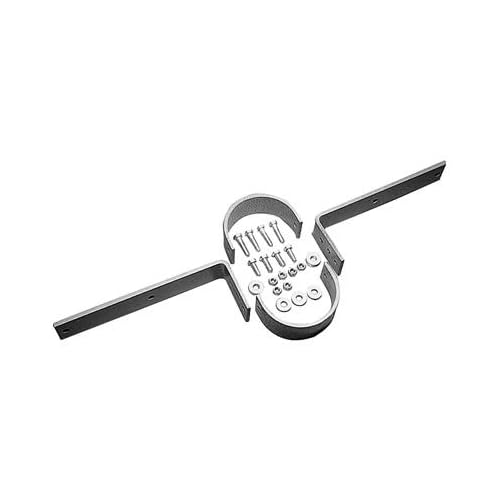

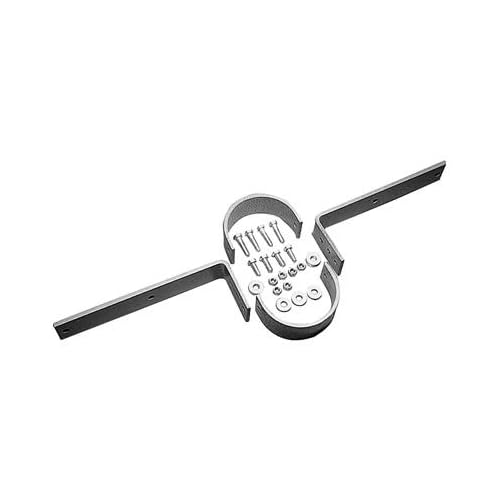

Think I will go with this universal kit -

The front spring mount is a natural “hinge” in the chassis structure where the rear sub frame joins the body tub and X member. Most if not all Tigers have cracks there and it is only made worse with more HP.

30 minutes work and the rear axle is easily out.

This is the left side that I have not touched yet. Looks OK but will know for sure once I start cleaning the area up.

Right side after lots of scraping, wire brush, grinder...etc. Still needs more prep. There are indications of welding to the left of the mount.

The reinforce plates. You can see the plates for the right side that I have been shaping and grinding to fit.

A friend of mine will bring his MIG rig over this weekend and then we will get everything welded in.

More to follow.

While I am at it, I am going to install a drive shaft loop.

Think I will go with this universal kit -

Last edited by Duke on Dec 06, 2010 10:54 AM, edited 1 time in total.

I have removed the original panhard rod (its in my basement). Rootes actually installed them the wrong way (they fixed it with the MK II's). They end up pulling out of the mount on the body. I removed mine before any of this damage was done. You can see the bracket on the axle for it.Coldswede wrote:Duke, does Le Tiger use the springs to prevent lateral movement of the differential of is there a Panhard rod in there someplace?

The springs I have are aftermarket and are much stronger that stock. You can see the addition 1/2 leaf that runs forward a wraps around a bushing. This is in addition to fewer and much thicker leaf springs than stock. They allow me to run without traction bars or a panhard rod. That is with the 260 though. There are lots of different options that have been developed over the years for higher HP applications. I will need to do some more research.

It had traction bars when I bought it. They were both bent. They are also in my basement. I throw nothing away.

Last edited by Duke on Dec 06, 2010 11:07 AM, edited 4 times in total.

Progress -

Right side is about ready. Screws are to hold pieces in place for welding. The bolt is to insure the plate is perfectly placed. They will then be removed and screw holes filled. Once everything is tacked in place a hammer can be use to shape the pieces for smaller gaps for welding.

I NEED A LIFT.

Start on the left side tonight. It should go much quicker due to my experience on the right side.

Right side is about ready. Screws are to hold pieces in place for welding. The bolt is to insure the plate is perfectly placed. They will then be removed and screw holes filled. Once everything is tacked in place a hammer can be use to shape the pieces for smaller gaps for welding.

I NEED A LIFT.

Start on the left side tonight. It should go much quicker due to my experience on the right side.

http://www.youtube.com/watch?v=QBKsyzm0WCoDuke wrote:This guy has and is running 9.55 quarters.Soco wrote:Really in the end, forced induction always wins. Now if you were to twin turbo it, then it would be scary and cooler.

http://teae.org/forum/viewtopic.php?f=2 ... 7423#p7423

So.......there is always someone faster.swatterssr wrote:http://www.youtube.com/watch?v=QBKsyzm0WCo

http://www.youtube.com/watch?v=EshwwzFZUMs

Great looking reinforcing job. are you gonna add a triangular bracket to cut down on the side thrust?Duke wrote:Progress -

Right side is about ready. Screws are to hold pieces in place for welding. The bolt is to insure the plate is perfectly placed. They will then be removed and screw holes filled. Once everything is tacked in place a hammer can be use to shape the pieces for smaller gaps for welding.

I NEED A LIFT.

Start on the left side tonight. It should go much quicker due to my experience on the right side.

Yeah, I know.Duke wrote:So.......there is always someone faster.swatterssr wrote:http://www.youtube.com/watch?v=QBKsyzm0WCo

http://www.youtube.com/watch?v=EshwwzFZUMs

Just messing with you... though mine was a Bimmer.

You truly have a nice car Duke.

I'm looking forward to making eye contact and possibly even getting some seat time,

as the co-pilot of course,

as long as the safety restrain system is installed securely.

Welding today.

My friend, Russ, did a yeomans job on his back today. 1/2 way through the second mount, the gas ran out. Got a new bottle from TSC and will finish tomorrow.

Here is the "universal" drive shaft loop ready to install in the Tiger. I had to do quite a bit of cutting and drilling to make it work.

My friend, Russ, did a yeomans job on his back today. 1/2 way through the second mount, the gas ran out. Got a new bottle from TSC and will finish tomorrow.

Here is the "universal" drive shaft loop ready to install in the Tiger. I had to do quite a bit of cutting and drilling to make it work.

I'm sure we can arrange something.1st 5er wrote:I'm looking forward to making eye contact and possibly even getting some seat time,

as the co-pilot of course, as long as the safety restrain system is installed securely.

-

Alfonso Bedoya

- Posts: 1326

- Joined: Sep 16, 2010 3:15 PM

- Location: Van Isle, B.C. Canada

Here is a link to some tiger books Duke I thought I'd wish you a merry xmas too!

http://vancouver.en.craigslist.ca/van/p ... 75624.html

http://vancouver.en.craigslist.ca/van/p ... 75624.html

-

Alfonso Bedoya

- Posts: 1326

- Joined: Sep 16, 2010 3:15 PM

- Location: Van Isle, B.C. Canada

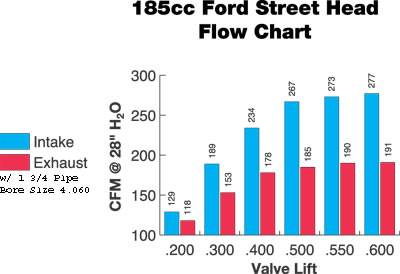

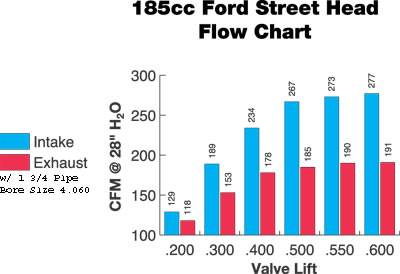

Getting ready to pull the trigger on the heads.

I am going with AFR 185 #1388 heads. They run ~$1500 a pair new. I found a set on Craigs list for $900 with "upgraded" comp springs.

The seller states that they have 3K miles on them and are in great shape. I have asked for pictures and will call him next week. I am a little weary of used parts but saving $700 (I would offer $800) would be great.

2.020" intake valves

1.600" exhaust valves

58cc combustion chambers

68cc exhaust ports

There is also a 70 lb saving from iron heads. The new engine will have more than twice the HP of stock and ~90lbs less weight.

I am going with AFR 185 #1388 heads. They run ~$1500 a pair new. I found a set on Craigs list for $900 with "upgraded" comp springs.

The seller states that they have 3K miles on them and are in great shape. I have asked for pictures and will call him next week. I am a little weary of used parts but saving $700 (I would offer $800) would be great.

2.020" intake valves

1.600" exhaust valves

58cc combustion chambers

68cc exhaust ports

There is also a 70 lb saving from iron heads. The new engine will have more than twice the HP of stock and ~90lbs less weight.