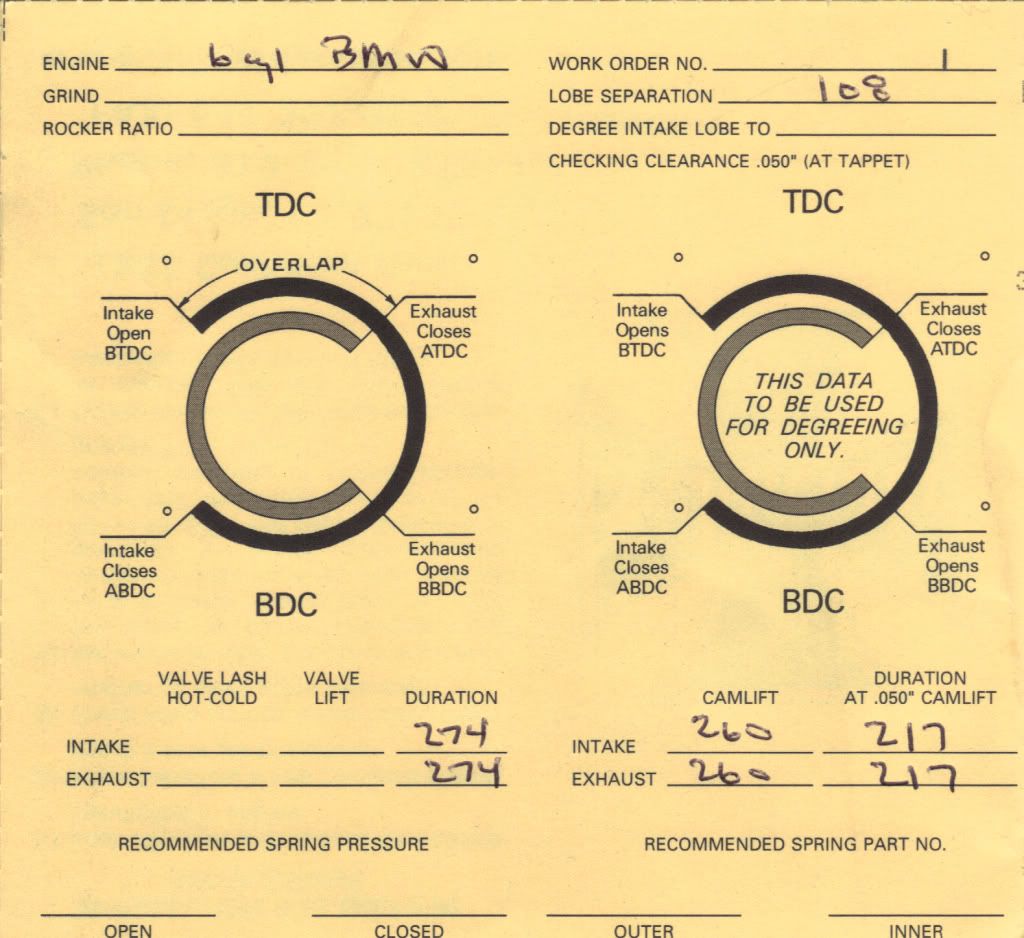

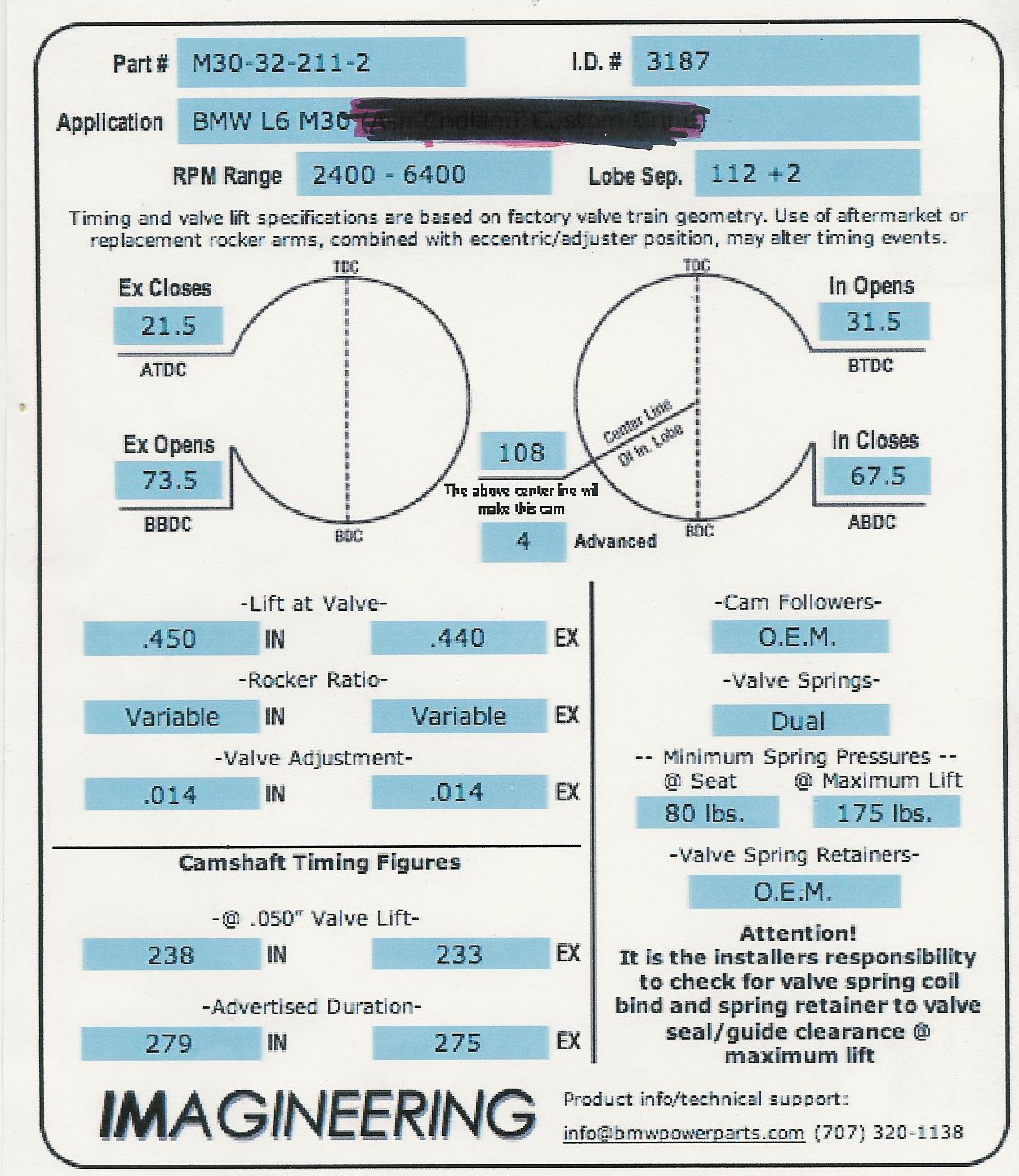

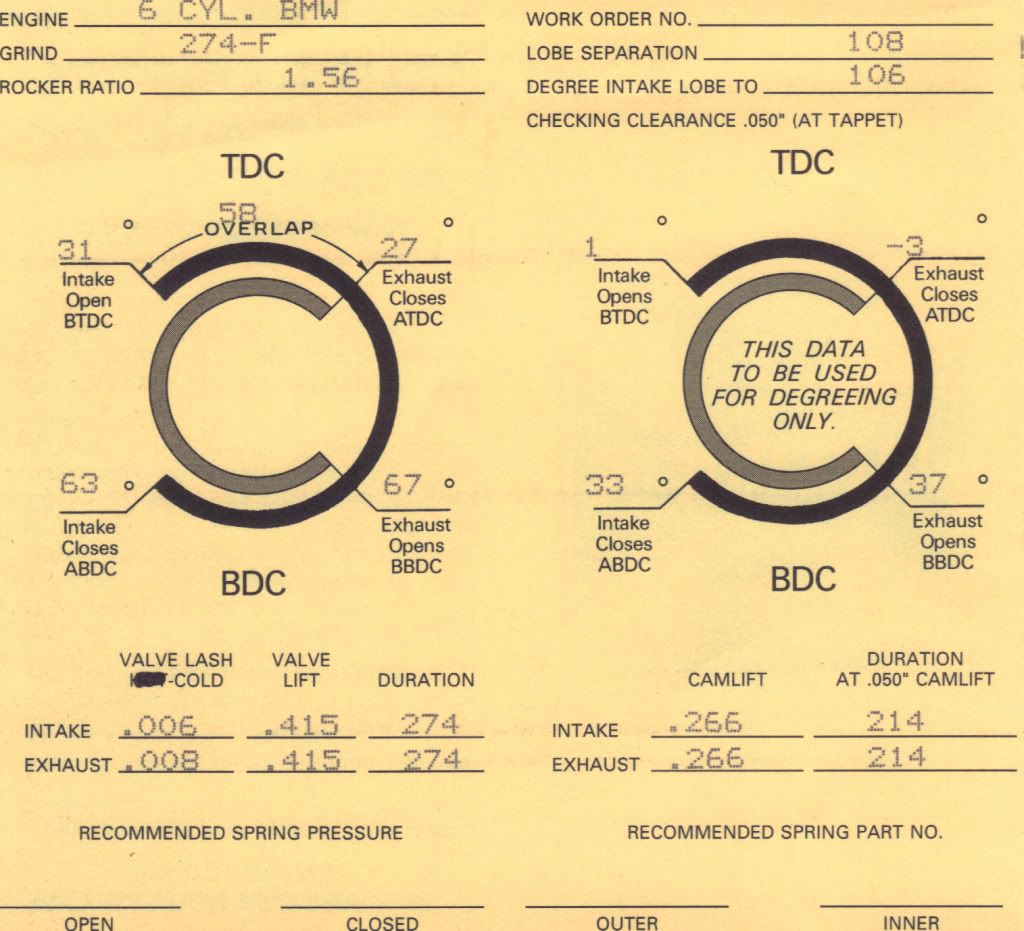

Devinder, I was also interested in you method of measuring m30 profiles (m10, m20 also). Are you incorporating lash into these measurements and how did you arrive at the 272 number for your 280 Schrick? Most cam manufacturers generate advertised numbers at the trailing (opening) and leading (closing) edges of the clearance ramps (I believe Schrick uses .012 as a checking height), if you go outside those numbers depending on clearance ramp rate the duration numbers will be out of proportion and not a true indicator of the camshafts potential.

Can you post the opening and closing numbers of your 280 Schrick intake lobe and the checking height or heights (@zero lash) you used?

Paul

Paul,

All measurements were done according to SAE J604. I can send you that standard if you don't have it.

All measurements were done with zero lash so I could map the clearance ramps. On the M30, I adjusted the eccentric until the valve was off the seat (and the rocker was on the base circle). The dial indicator was on the retainer and followed the valve movement directly. On the S38, I used a pair of v-blocks on a granite plate to spin the cam. I have a custom tip for the dial indicator made out of a valve shim so the wipe area is the same. I think I posed pictures on this forum at one time; or maybe I sent them to someone. I'll see if I can find the setup pictures.

I agree that the after-market manufacturers use the clearance ramps for specifying duration. I measured duration at the SAE J604 standard height. I forget what it is right now, but it turns out that those duration numbers are very close to BMW's advertised numbers so I think BMW uses the SAE standard. I think the SAE standard height gets you off the ramps. The American after-market cam makers do the same thing by specifying duration at 0.050" lift so you can compare different cams.

Your question about the S38 duration: I would just read it off the chart for whatever checking height you want. I think I've drawn both SAE and American checking heights on the chart.

Keep in mind that the SAE standard calculates the checking height as a function of the manufacturer's lash setting so it will vary for different cams.

Devinder