External links now open in a new browser tab - turn this off in your UCP - Read more here.

Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Did you see the link I posted above?

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

wkohler wrote:Did you see the link I posted above?

Dammit. I did and then read back to catch up, then forgot, then tried to edit and you STILL got me.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

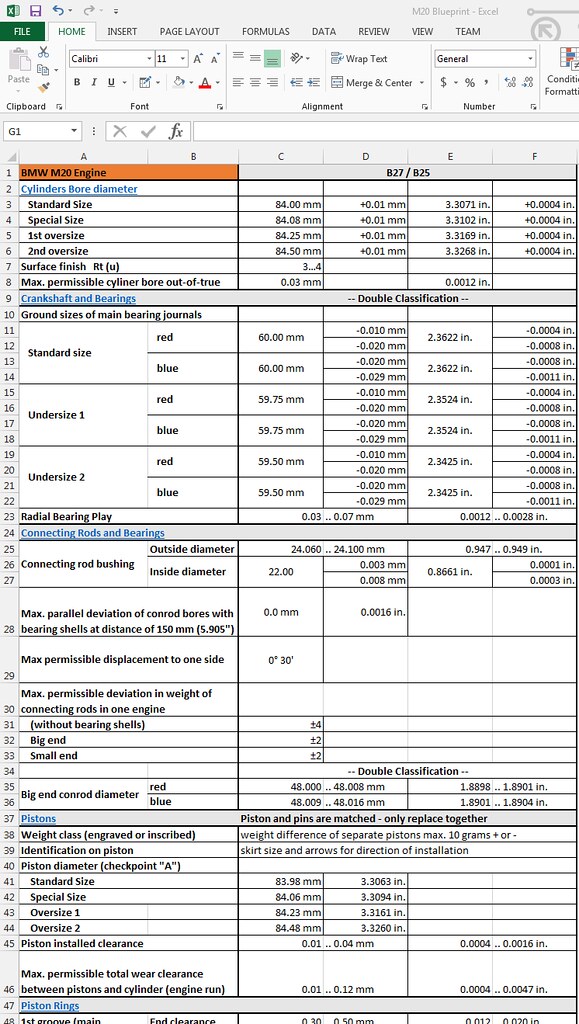

But THIS is better. Because I made it, and because it will enable to me to build my blueprint sheet such that it does the math for me.ldsbeaker wrote:Dammit. I did and then read back to catch up, then forgot, then tried to edit and you STILL got me.wkohler wrote:Did you see the link I posted above?

Entering and verifying all those numbers, and setting up the metric->imperial formulas and using THOSE to double check against the originals has already helped me to have a clearer picture of the numbers and how they relate. I'll share this XLS when done...

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Oh what the fuck ever.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

10 gram weight difference between pistons?

Aim for 1 gram, same as the conrods.

A 10 gram tolerance might be ok on a large manufacturers production line, but when you are doing a rebuild yourself, this is when you can take advantage of being meticulous and further refine the motor.

Weight match all the pistons and rods, even clean up the rods of unnecessary weight around the little ends, can even go to the extent of internally deburring the block of rough casting to aid in oil drainback to the sump (even painting the inside walls), match porting the head oil drains to the block and enlarging them, not required on a street motor, but oil control is a big issue on a track car, it's just more practice if you wanted to do it, free other than the labour involved.

Aim for 1 gram, same as the conrods.

A 10 gram tolerance might be ok on a large manufacturers production line, but when you are doing a rebuild yourself, this is when you can take advantage of being meticulous and further refine the motor.

Weight match all the pistons and rods, even clean up the rods of unnecessary weight around the little ends, can even go to the extent of internally deburring the block of rough casting to aid in oil drainback to the sump (even painting the inside walls), match porting the head oil drains to the block and enlarging them, not required on a street motor, but oil control is a big issue on a track car, it's just more practice if you wanted to do it, free other than the labour involved.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

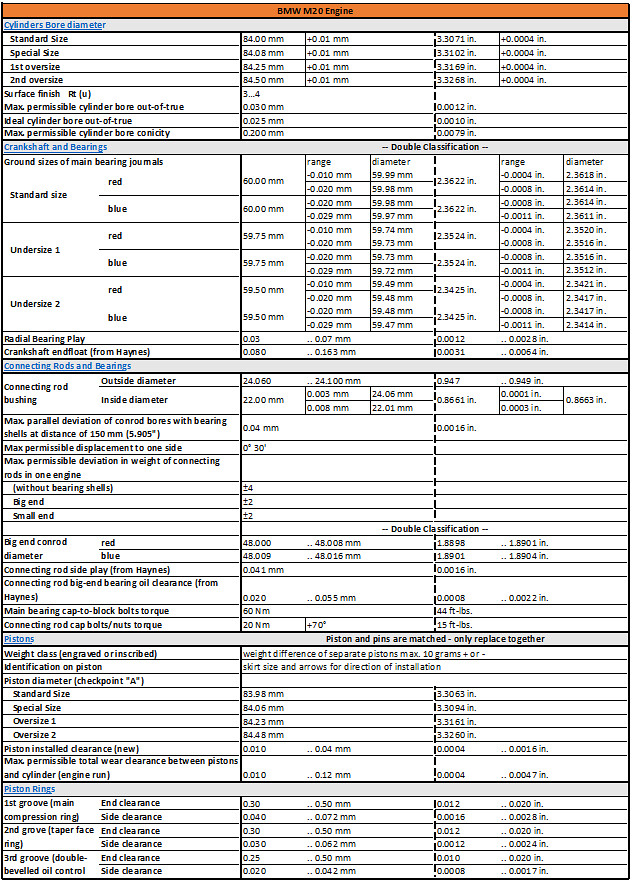

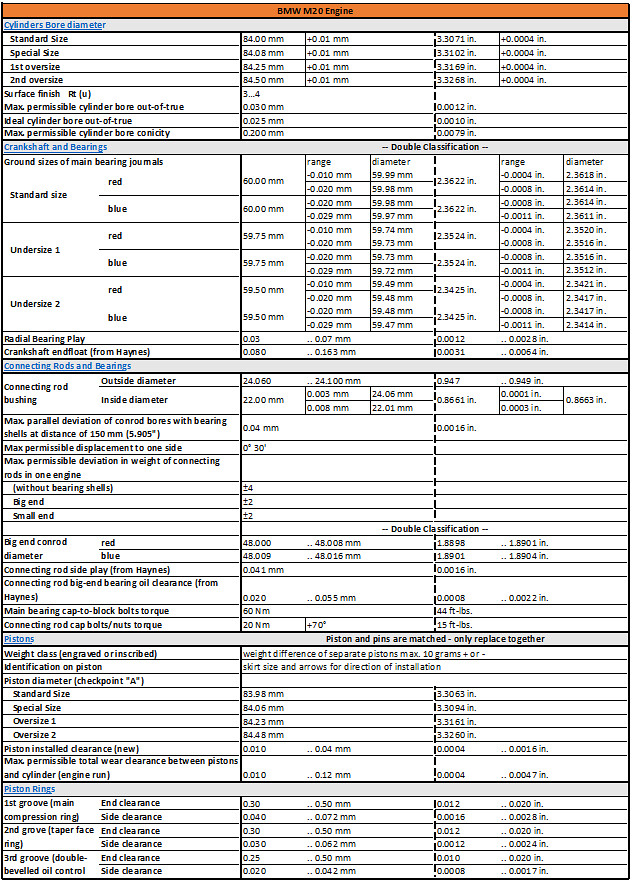

I still need to cross-reference with Bentley but I have just about every measurement now documented in my M20 Blueprint spreadsheet.

I really like having all this in one place. I'll continue to update it as I learn more.

M20 Blueprint

M20 Blueprint

If anyone notices any errors, or measurements that should/could be tighter/looser based on real experience I'd appreciate it. I'll add them.

I'm now going to add the ability to enter measurements while I take them, letting Excel do the math and report results.

I really like having all this in one place. I'll continue to update it as I learn more.

M20 Blueprint

M20 BlueprintIf anyone notices any errors, or measurements that should/could be tighter/looser based on real experience I'd appreciate it. I'll add them.

I'm now going to add the ability to enter measurements while I take them, letting Excel do the math and report results.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

wkohler wrote:Oh what the fuck ever.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

The only other thing i'll add is that if you are running an aftermarket forged piston and rings, bore/hone the block to their recommended specs.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Yep. Current plan is to use the Seta pistons i have. I'm still getting the hang of using my new outside micrometers, but my initial measurements of the pistons show they are well within spec.stoney wrote:The only other thing i'll add is that if you are running an aftermarket forged piston and rings, bore/hone the block to their recommended specs.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Which spec? The real BMW spec, the maybe correct Bentley spec or some other spec you created because you thought it was better?cek wrote:Yep. Current plan is to use the Seta pistons i have. I'm still getting the hang of using my new outside micrometers, but my initial measurements of the pistons show they are well within spec.stoney wrote:The only other thing i'll add is that if you are running an aftermarket forged piston and rings, bore/hone the block to their recommended specs.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Imperial? it's bad enough when people on the Board constantly insist on rounding off the exhaust sizes to Imperial, but engine tolerances? For fucks sake, why are Americans so terrified of the metric system?cek wrote:Entering and verifying all those numbers, and setting up the metric->imperial formulas

Charlie, I know your newish but a search will show that this is probably my all time number one peeve. I'm talking waaaay above world hunger and global warming.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

It's pretty clear if you are doing this sort of engine work, you need to deal with both.Karl Grau wrote:Imperial? it's bad enough when people on the Board constantly insist on rounding off the exhaust sizes to Imperial, but engine tolerances? For fucks sake, why are Americans so terrified of the metric system?cek wrote:Entering and verifying all those numbers, and setting up the metric->imperial formulas

Charlie, I know your newish but a search will show that this is probably my all time number one peeve. I'm talking waaaay above world hunger and global warming.

First, most people discuss the measurements in inches.

Second, and I suspect this is why the first is true, is most micrometers are Imperial. Metric micrometers are far more rare and more expensive.

I'm with you Charles: If I could do it all metric I would.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Haha, soo true.Karl Grau wrote:For fucks sake, why are Americans so terrified of the metric system?

Charlie, do you plan on weight matching everything? or just sticking with a 10gram maximum difference? or should that be 0.35274 ounces

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Fortunately my scale works in gramsstoney wrote:Charlie, do you plan on weight matching everything? or just sticking with a 10gram maximum difference? or should that be 0.35274 ounces

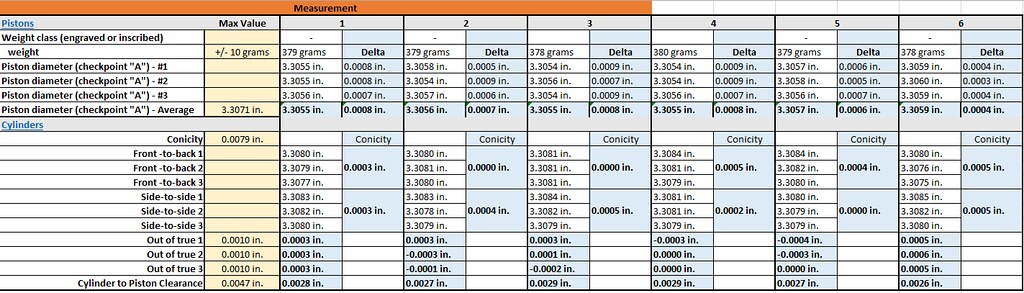

I just weighed all the pistons. They are all 379 grams +/- 1 gram.

I also weighed my new fancy rods and they are all exactly 550 grams (the original rods are ~642 grams.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

I have no idea what I'm doing, but I sure am having fun.

This stuff is awesome. Makes cleaning pistons super easy.

I got out my new bore/cylinder gauge and figured out how to use it. I'm not 100% sure I have it calibrated yet but I have numbers that are not outrageous. Going just by what I see for cyl #1 and #2 this 360k block is not worn much at all. Conicity (taper) is only .0013" (max permissible is .0079"). #1 is .0017" out of true at the bottom which is beyond spec (0.010"). Cylinder to piston clearance is only 0.0022" which is way less than 0.0047" which is max permissible.

I have low confidence in these numbers because I'm sorta struggling with using my outside micrometer on the pistons and I'm not convinced my bore gauge is calibrated right. If they are right, I'd still be junking this block and hoping the other one I'm buying that only has ~100k on it will be tighter.

I'm looking forward to measuring the crank tomorrow. When I removed the rods, there's quite a bit of wear on the sleeves, and the bearing surfaces on the crank are worn pretty good. It will be very educational finding out how much wear is actually associated with what's visible.

This stuff is awesome. Makes cleaning pistons super easy.

I got out my new bore/cylinder gauge and figured out how to use it. I'm not 100% sure I have it calibrated yet but I have numbers that are not outrageous. Going just by what I see for cyl #1 and #2 this 360k block is not worn much at all. Conicity (taper) is only .0013" (max permissible is .0079"). #1 is .0017" out of true at the bottom which is beyond spec (0.010"). Cylinder to piston clearance is only 0.0022" which is way less than 0.0047" which is max permissible.

I have low confidence in these numbers because I'm sorta struggling with using my outside micrometer on the pistons and I'm not convinced my bore gauge is calibrated right. If they are right, I'd still be junking this block and hoping the other one I'm buying that only has ~100k on it will be tighter.

I'm looking forward to measuring the crank tomorrow. When I removed the rods, there's quite a bit of wear on the sleeves, and the bearing surfaces on the crank are worn pretty good. It will be very educational finding out how much wear is actually associated with what's visible.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

There's almost no conicity (taper) on this block.

The bores are also almost round; well within spec.

It wore very uniformly. At ~0.0028" cylinder to piston clearance I could slap this back together and still be way within max (0.0047").

Kinda mind-blowing for a 360k block. The pistons account for much of the wear.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

I'll bet that crank can be polished out just fine. Can you feel that scuffing with your thumbnail?

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Crank bearings are worn. Connecting rod bearing diameter is 1.7705-1.7709" with minimum spec being 1.7707".ldsbeaker wrote:I'll bet that crank can be polished out just fine. Can you feel that scuffing with your thumbnail?

Main bearing diameters are 2.3609-2.3613" with minimum spec being 2.3614".

Of course, it could be ground down to next size. But I have another crank incoming anyway.

I did not use plastiguage to measure the radial clearances. Out of time for today. But I plan on doing it for the main bearings and caps sometime soon just to get the experience. Never used platsigauge before...

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Flexigauge is very easy to use, just do it so there is no weight on them, I.E, the crank, so if you are measuring main clearances, do it with the motor upside down so the cranks weight is going on the block side and not the main cap side, obviously don't rotate the motor either, and dont use any oil/lube.

When I first used it, I had no clue, but worked it out straight away, its not rocket surgery.

When I first used it, I had no clue, but worked it out straight away, its not rocket surgery.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

You seriously need to find new 'people'.cek wrote: First, most people discuss the measurements in inches.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Me being in Australia, I don't have the issue of dealing with imperial unless the person is over 60, but I see it this way, if the engine builder you are dealing with works only on big block chevs and works in inches, then stick with his way, if you start confusing him with metric conversions etc, something could be machined incorrectly.

Same as an engine ECU tuner, if they specialise in a certain brand, use that brand, don't come to them with a WAR chip if they only know how to tune a megasquirt, and vice versa.

Granted, the metric system can be measured accurately on the smaller scale a lot more easily, but again, only if the person knows how and has the right tools

Same as an engine ECU tuner, if they specialise in a certain brand, use that brand, don't come to them with a WAR chip if they only know how to tune a megasquirt, and vice versa.

Granted, the metric system can be measured accurately on the smaller scale a lot more easily, but again, only if the person knows how and has the right tools

-

2 5's and a 7

- Posts: 653

- Joined: Jul 08, 2014 2:32 PM

- Location: Fayetteville AR

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

I've got a scale that will weigh a dollar bill.......found it in a car I repoed twenty something years ago, also had a lot of empty ziplock bags in it.cek wrote:Fortunately my scale works in gramsstoney wrote:Charlie, do you plan on weight matching everything? or just sticking with a 10gram maximum difference? or should that be 0.35274 ounces

I just weighed all the pistons. They are all 379 grams +/- 1 gram.

I also weighed my new fancy rods and they are all exactly 550 grams (the original rods are ~642 grams.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Two 325i M20 throttle bodies. One has a broken spring holder. They have different vacuum attachment thingies. I'm wondering which one will be the right one to use.

Oil pump cleaned (mostly). Gears show no wear.

Cleaned up a bunch of other parts today too.

Hopefully I'll be able to pick up the 'new' block and crankshaft this week.

Oil pump cleaned (mostly). Gears show no wear.

Cleaned up a bunch of other parts today too.

Hopefully I'll be able to pick up the 'new' block and crankshaft this week.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Pump looks to be in good shape but you should check clearance between gear and pump body, between cover and gears and backlash between gears. Procedure and specs are probably in Bentley.cek wrote:Two 325i M20 throttle bodies. One has a broken spring holder. They have different vacuum attachment thingies. I'm wondering which one will be the right one to use.

Oil pump cleaned (mostly). Gears show no wear.

Cleaned up a bunch of other parts today too.

Hopefully I'll be able to pick up the 'new' block and crankshaft this week.

The two throttle bodies are identical, 2nd one is just missing the pressfit elbow thingie.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

I think the pair of "vacuum attachment thingies" have coolant hoses connected to them. If you use the TB on the left, and the flange on the other is in decent shape, just swap it over. Otherwise new replacement aftermarket flanges are pretty cheap; under $4 at ECS Tuning. And I think the larger pipe just presses in.burmester wrote:The two throttle bodies are identical, 2nd one is just missing the pressfit elbow thingie.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

I would not bother with the coolant lines for the throttle heat unless you live and use the car where freeze over of the T/B might occur. One simply has the barbs sawed off and looks like it was the eta rather than i version of the housing to begin with. They use a cork like gasket and tend to leak eventually and then the screws may break when you pull it apart only to find the casting is rotten too. An M30 has no T/B heat and I've never heard of one freezing up. On an airplane you need carb heat but probably not an M20.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

That was my thinking too, simplify the cooling system by eliminating two more hoses, or reuse that hose for the turbo coolant feed/return lines

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

I know you were wondering, but yes, this project continues. Today I picked up another M20 block and crank from the same guy I bought the head from. I should have just bought it all from him to start with. This block is freshly honed/decked and the crank polished. It doesn't have the dipstick tube and I ruined the one in the old block trying to get it out (someday I'll learn patience), so now I'm searching for a good used M20 dipstick tube.

I need to measure everything on the new block and paint it. Then I'll order main bearings, rings, and a few other parts and I can start assembling it...

I need to measure everything on the new block and paint it. Then I'll order main bearings, rings, and a few other parts and I can start assembling it...

Last edited by tig on Jan 17, 2016 10:07 PM, edited 1 time in total.

-

KrautnotRice

- Posts: 386

- Joined: Dec 28, 2014 2:32 AM

- Location: South Carolina

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Eggsellent...

Looking forward to more progress.

Looking forward to more progress.