External links now open in a new browser tab - turn this off in your UCP - Read more here.

T-build.SHE'S ALIVE!!!!!!!

aint that the truth! FAST though......shocka wrote:Isnt that always the way v12 Jag's are TERRIBLE.grey ghost wrote:They said Friday but there was a v12 jag ahead of me that was holding things up.ceebee9 wrote:ANY IDEA WHEN THE HEAD WILL BE READY AT THIS POINT? By or after tomorrow?

I'll send you a text this evening.

-

grey ghost

- Posts: 3038

- Joined: Feb 12, 2006 12:00 PM

- Location: Falls Church VA

So the v12 has indeed held me up and I wont get the head back today.ceebee9 wrote:aint that the truth! FAST though......shocka wrote:Isnt that always the way v12 Jag's are TERRIBLE.grey ghost wrote:They said Friday but there was a v12 jag ahead of me that was holding things up.ceebee9 wrote:ANY IDEA WHEN THE HEAD WILL BE READY AT THIS POINT? By or after tomorrow?

I'll send you a text this evening.

-

grey ghost

- Posts: 3038

- Joined: Feb 12, 2006 12:00 PM

- Location: Falls Church VA

-

grey ghost

- Posts: 3038

- Joined: Feb 12, 2006 12:00 PM

- Location: Falls Church VA

I'm sitting here on sabbatical, trading a little on the forex market, waiting for these guys to finish this jag and get my head done.Brad D. wrote:Won't be the last time a Jag makes someone miserable.grey ghost wrote:Jag still killing me, never found that center section.....ceebee9 wrote:yo! whats the VERDICT Grey ghost?

is that Jag still holding you up?

Hey man you ever come across that missing piece of plastic?

Very painfull.

They have had it for a week now.

The killer is arranging for help to get the head back on.

Its not like everyone else is on sabbatical as well......

I'm in "hurry up and wait" mode................

-

grey ghost

- Posts: 3038

- Joined: Feb 12, 2006 12:00 PM

- Location: Falls Church VA

-

grey ghost

- Posts: 3038

- Joined: Feb 12, 2006 12:00 PM

- Location: Falls Church VA

Got the head on

And yes its timed right this time.

The valves need to be adjusted.

The motor spins smoothly by hand.

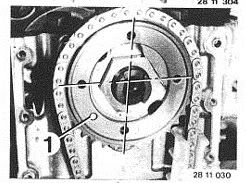

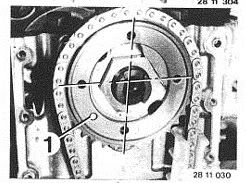

So with the cam in the below position and the OT on the vibration damper set to the peg on the block I locked it in.

But I have one question.

Does the cam spin 1/2 revolution for every one complete turn of the motor?

As you can see in the picture, the sprocket dowel is in the 7:30 position.

I spun the motor 1 complete revolution and found the dowel the in 2:30 position and I almost crapped myself.

Of course I spun it one more revolution and it was back in the 7:30 position.

I know that since the crank and cam sprockets are a different size, rotation wont be 1:1. My educated guess is that the cam sprocket as twice has many teeth.........

If all goes well I hope to breath some life into her tomorrow.

And yes its timed right this time.

The valves need to be adjusted.

The motor spins smoothly by hand.

So with the cam in the below position and the OT on the vibration damper set to the peg on the block I locked it in.

But I have one question.

Does the cam spin 1/2 revolution for every one complete turn of the motor?

As you can see in the picture, the sprocket dowel is in the 7:30 position.

I spun the motor 1 complete revolution and found the dowel the in 2:30 position and I almost crapped myself.

Of course I spun it one more revolution and it was back in the 7:30 position.

I know that since the crank and cam sprockets are a different size, rotation wont be 1:1. My educated guess is that the cam sprocket as twice has many teeth.........

If all goes well I hope to breath some life into her tomorrow.

I think your supposed to spin the motor 2 full revolutions, it being a 4stroke and not a 2 stroke, and then make sure the marks line up again.

Then again I am the retarded one that just went thru rebuilding an engine to only have an oil leak that I can't figure out where it is or how to fix it. So take my advice with a shot of JD and it might make sense.

Then again I am the retarded one that just went thru rebuilding an engine to only have an oil leak that I can't figure out where it is or how to fix it. So take my advice with a shot of JD and it might make sense.

-

grey ghost

- Posts: 3038

- Joined: Feb 12, 2006 12:00 PM

- Location: Falls Church VA

2 complete revs got the dowel back in the right position.jim325 wrote:I think your supposed to spin the motor 2 full revolutions, it being a 4stroke and not a 2 stroke, and then make sure the marks line up again.

Then again I am the retarded one that just went thru rebuilding an engine to only have an oil leak that I can't figure out where it is or how to fix it. So take my advice with a shot of JD and it might make sense.

-

grey ghost

- Posts: 3038

- Joined: Feb 12, 2006 12:00 PM

- Location: Falls Church VA

-

grey ghost

- Posts: 3038

- Joined: Feb 12, 2006 12:00 PM

- Location: Falls Church VA

The build is officially terminated!

I installed the head, timed it right, I believe, may have been off by a tooth.

Spun the motor by hand at least ten time.... and still managed to break a rocker arm on the #6 cylinder.

I'm done........

Major waste................. And I'd like to say I have no regrets, but I can't.

I will be posting the part out on the "parts for sale" board.

Thanks for all your help.

I installed the head, timed it right, I believe, may have been off by a tooth.

Spun the motor by hand at least ten time.... and still managed to break a rocker arm on the #6 cylinder.

I'm done........

Major waste................. And I'd like to say I have no regrets, but I can't.

I will be posting the part out on the "parts for sale" board.

Thanks for all your help.

Sorry to see this. What happened? Even if you decide to scrap the project (and I don't recommend it), it's worth knowing. Get someone over to check it out. Did the bottom end get decked or different rods/pistons get put in? Did the top end get milled?

Something is wrong here.

Rotten fucking luck. I understand your pain, but I urge you to push through it and figure out what got fucked up.

Good luck going forward, either in the rebuild or the sales.

Something is wrong here.

Rotten fucking luck. I understand your pain, but I urge you to push through it and figure out what got fucked up.

Good luck going forward, either in the rebuild or the sales.

-

grey ghost

- Posts: 3038

- Joined: Feb 12, 2006 12:00 PM

- Location: Falls Church VA

Well, at this point I'm somewhere between depressed and discusted.Xenocide wrote:Sorry to see this. What happened? Even if you decide to scrap the project (and I don't recommend it), it's worth knowing. Get someone over to check it out. Did the bottom end get decked or different rods/pistons get put in? Did the top end get milled?

Something is wrong here.

Rotten fucking luck. I understand your pain, but I urge you to push through it and figure out what got fucked up.

Good luck going forward, either in the rebuild or the sales.

I have no idea what went wrong.

I timed it, spun by hand a good ten times, did the valve job, tripple checked them by spinning the motor, and rechecking and spinning the motor again.....

I started the motor and it was making a ton of knocking noise.

It sounded like it was coming from the valves.

I pulled the valve cover back off and inspected the adjustment I had just done.

Everything was fine. The adjustment was good and at this point, the rocker arm was not broken.

With a little research I decided to go back in and check my timing. I was off by one tooth.

So I fixed that and and spun the motor, it got hung up and thats when I look to the rear of the head and saw the broken arm.

One tooth should NOT have been enough to break a rocker. I'm not very familiar with the big six, but I know that much. Something else is going on here. Not sure what, but have yourself a beer, calm down, and let someone who is very familiar with the chain drive beast chime in.

Sorry again, I know it's the worst feeling in the world.

Sorry again, I know it's the worst feeling in the world.

-

Nebraska_e28

- Beamter

- Posts: 9072

- Joined: Apr 13, 2006 11:18 PM

- Location: Council Bluffs, IA

- Contact:

-

grey ghost

- Posts: 3038

- Joined: Feb 12, 2006 12:00 PM

- Location: Falls Church VA

I would love to move on but I obviously don't have the skills, and my budget has been busted.Nebraska_e28 wrote:Wish me & the crew were a little closer, we'd come over & try to diagnose things over a 24 pack! I feel your pain. Take a break & then push on. You'll be rewarded once converted to the dark side. <insert darth vader icon here>

In honesty, I don't think it was all my fault.

I too wish you were closer. I have no one here with the skills I need to get thru this.

-

Nebraska_e28

- Beamter

- Posts: 9072

- Joined: Apr 13, 2006 11:18 PM

- Location: Council Bluffs, IA

- Contact:

I have a spare head on a motor in the back that's been sitting I'll give you for the price of shipping if you wanna try to go 1 out of 3 tries.grey ghost wrote:I would love to move on but I obviously don't have the skills, and my budget has been busted.Nebraska_e28 wrote:Wish me & the crew were a little closer, we'd come over & try to diagnose things over a 24 pack! I feel your pain. Take a break & then push on. You'll be rewarded once converted to the dark side. <insert darth vader icon here>

In honesty, I don't think it was all my fault.

I too wish you were closer. I have no one here with the skills I need to get thru this.

-

Nebraska_e28

- Beamter

- Posts: 9072

- Joined: Apr 13, 2006 11:18 PM

- Location: Council Bluffs, IA

- Contact:

x2 I think you'd feel some binding, unless you were cranking it with a breaker bar.turbodan wrote:The rocker arm may have been damaged during the last episode. I'm planning on replacing all 12 before I out my turbo motor back together. They're not meant to handle that kind of stress. If you were able to spin the motor over by hand it certainly wasn't caused by interference.

-

grey ghost

- Posts: 3038

- Joined: Feb 12, 2006 12:00 PM

- Location: Falls Church VA

I was using a rachet with the big socket on the crank nut.Nebraska_e28 wrote:x2 I think you'd feel some binding, unless you were cranking it with a breaker bar.turbodan wrote:The rocker arm may have been damaged during the last episode. I'm planning on replacing all 12 before I out my turbo motor back together. They're not meant to handle that kind of stress. If you were able to spin the motor over by hand it certainly wasn't caused by interference.

How can you turn a motor all bolted in literally by hand...

-

Nebraska_e28

- Beamter

- Posts: 9072

- Joined: Apr 13, 2006 11:18 PM

- Location: Council Bluffs, IA

- Contact:

Pull the spark plugs.grey ghost wrote:I was using a rachet with the big socket on the crank nut.Nebraska_e28 wrote:x2 I think you'd feel some binding, unless you were cranking it with a breaker bar.turbodan wrote:The rocker arm may have been damaged during the last episode. I'm planning on replacing all 12 before I out my turbo motor back together. They're not meant to handle that kind of stress. If you were able to spin the motor over by hand it certainly wasn't caused by interference.

How can you turn a motor all bolted in literally by hand...

-

grey ghost

- Posts: 3038

- Joined: Feb 12, 2006 12:00 PM

- Location: Falls Church VA

too lateNebraska_e28 wrote:Pull the spark plugs.grey ghost wrote:I was using a rachet with the big socket on the crank nut.Nebraska_e28 wrote:x2 I think you'd feel some binding, unless you were cranking it with a breaker bar.turbodan wrote:The rocker arm may have been damaged during the last episode. I'm planning on replacing all 12 before I out my turbo motor back together. They're not meant to handle that kind of stress. If you were able to spin the motor over by hand it certainly wasn't caused by interference.

How can you turn a motor all bolted in literally by hand...

-

Rich Euro M5

- Posts: 6098

- Joined: Mar 10, 2006 6:20 AM

- Location: Klein, Texas

How are you timing the camshaft to the crank? You hopefully know the M30 is a Slant - 6 and vertical (re: Bentley manual, Ch. 4, Fig 4-26, straight up and down) isn't referenced to the car's body. The straight up and down mentioned in the Bentley is the center line of the block which is perpendicular to the deck of the block. If you position the camshaft sprocket bolts referenced to the car body, you're going to bend valves.

Rich

Rich