External links now open in a new browser tab - turn this off in your UCP - Read more here.

Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Nice...

Something to realize above when you measure continuity after taking a connector apart is that you should see resistance on the load side due to whatever is connected. It is how you do a basic test that that device (in this case fuel pumps) has the proper resistance and is not burned up. Then if you test on the line or supply side with relay/switch open there should be no resistance to ground. With relay switch closed 12v+ on line side but don't measure in resistance mode with your meter on a live circuit or the meter may fry.

In any case I'm glad I was more or less correct and you did no damage to the engine harness. I've never really paid attention to how the oil level sensor works but now that I look at that I think you have a very isolated problem with just the oil level ground wire. Check that the oil level sensor housing was grounded to the engine by the screws, measure ohms. If near 0 very fortunate since even the oil switch that was closed (BU/VI) would have not seen any current due to the dead short. Otherwise current had to flow through to the check control and something attached to it may be toast.

Carry on...

Something to realize above when you measure continuity after taking a connector apart is that you should see resistance on the load side due to whatever is connected. It is how you do a basic test that that device (in this case fuel pumps) has the proper resistance and is not burned up. Then if you test on the line or supply side with relay/switch open there should be no resistance to ground. With relay switch closed 12v+ on line side but don't measure in resistance mode with your meter on a live circuit or the meter may fry.

In any case I'm glad I was more or less correct and you did no damage to the engine harness. I've never really paid attention to how the oil level sensor works but now that I look at that I think you have a very isolated problem with just the oil level ground wire. Check that the oil level sensor housing was grounded to the engine by the screws, measure ohms. If near 0 very fortunate since even the oil switch that was closed (BU/VI) would have not seen any current due to the dead short. Otherwise current had to flow through to the check control and something attached to it may be toast.

Carry on...

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

This. And it runs! Congratulations, and thank you for documenting the process.davintosh wrote:Also about the other OCD sufferers living vicariously through Charlie.athayer187 wrote:Remember, it's about the journey.cek wrote: Glad you are enjoying this. Part of me is enjoying this. The other part is annoyed at my stupidity and another part is full of angst that there's no way this motor is going to ever run.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

I want to be clear: I do NOT have OCD.SPF2006 wrote:This. And it runs! Congratulations, and thank you for documenting the process.davintosh wrote:Also about the other OCD sufferers living vicariously through Charlie.athayer187 wrote:Remember, it's about the journey.cek wrote: Glad you are enjoying this. Part of me is enjoying this. The other part is annoyed at my stupidity and another part is full of angst that there's no way this motor is going to ever run.

I have CDO.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Because the letters should be in alpha order goddamit...

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Back at it...

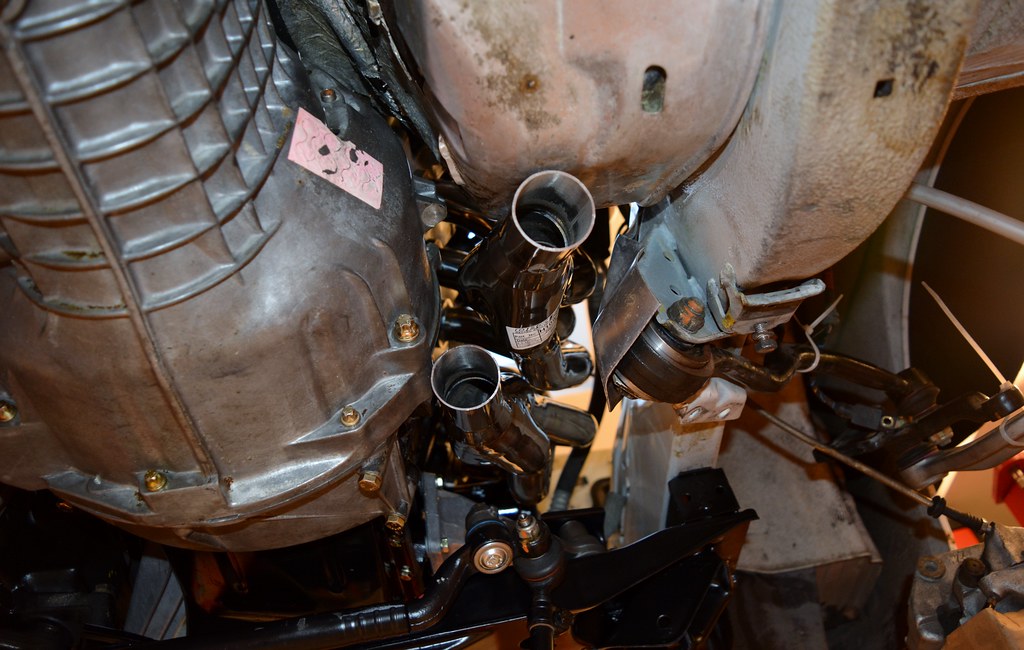

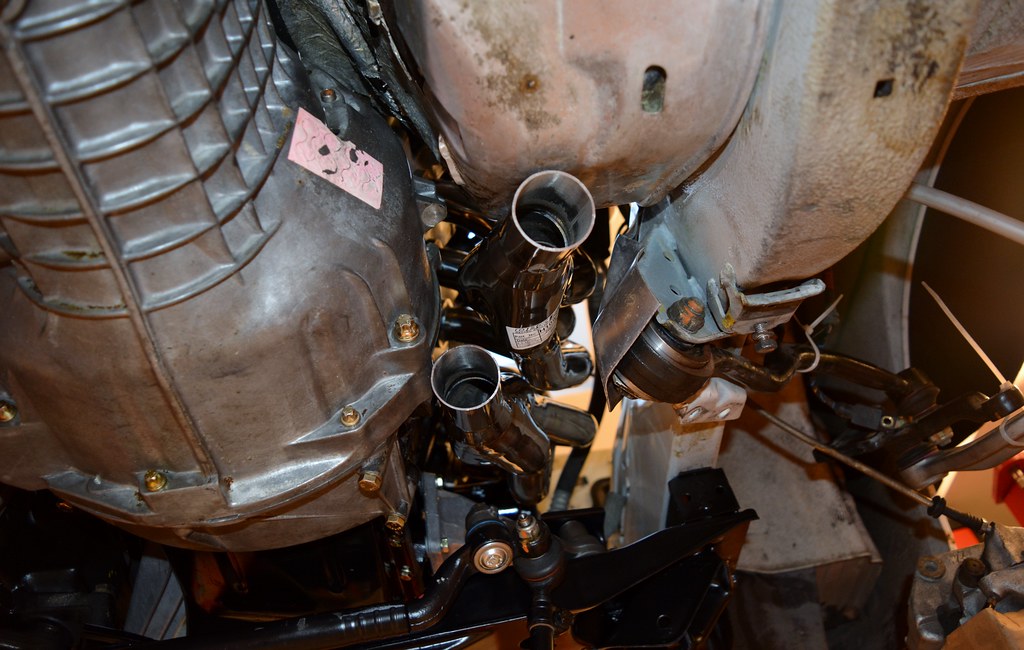

Before I put the original Eta exhaust on (temporarily) I want to ensure I fully understand the OBX headers. I may still go with them. Pics:

This is how they fit with the motor in the car.

Does this look right? It doesn't to me. Why are the outlets pointed in such different directions? I find it quite odd that the rear header (on the right) is pointing right (directionally) while the front is pointing correct (not right or left). Is there a logical reasons for this, or are just seeing poorly designed/built headers? I have very limited experience with headers so what do I know? The Bav Auto M30 headers on Vlad are long-tube headers and thus are totally different?

I don't think it will be particularly challenging to fabricate via mandrel pipe around this weirdness, but it just seems weird.

Other than that, they seem to fit pretty well.

Would love folks informed thoughts.

Before I put the original Eta exhaust on (temporarily) I want to ensure I fully understand the OBX headers. I may still go with them. Pics:

This is how they fit with the motor in the car.

Does this look right? It doesn't to me. Why are the outlets pointed in such different directions? I find it quite odd that the rear header (on the right) is pointing right (directionally) while the front is pointing correct (not right or left). Is there a logical reasons for this, or are just seeing poorly designed/built headers? I have very limited experience with headers so what do I know? The Bav Auto M30 headers on Vlad are long-tube headers and thus are totally different?

I don't think it will be particularly challenging to fabricate via mandrel pipe around this weirdness, but it just seems weird.

Other than that, they seem to fit pretty well.

Would love folks informed thoughts.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Uh.

The bolt on the idler arm ALMOST touches the headers. It's entirely likely that the motor moving around will impact steering. So if I DO go with the headers I'll have do to something about this.

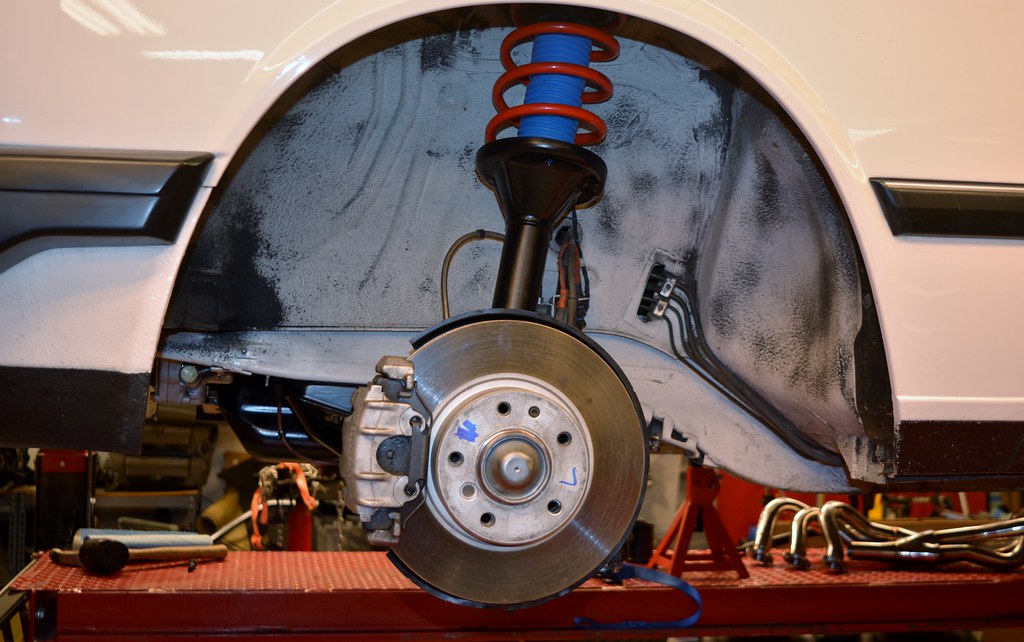

I am delighted to report that I made huge progress.

- Driveshaft hooked up

- Heat shield in place

- Cooling system all hooked up

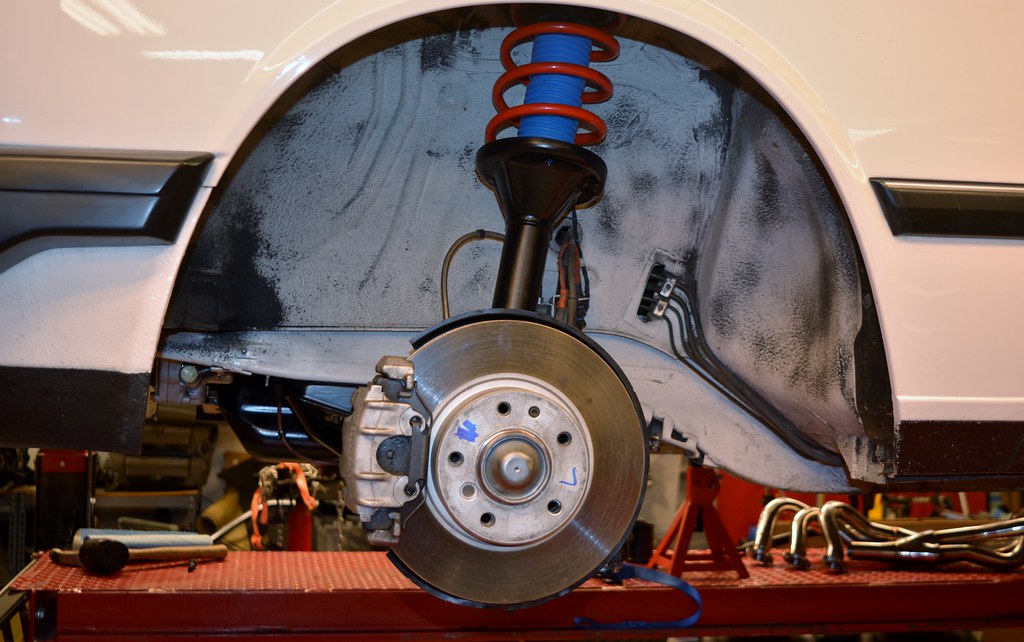

- Front suspension back together (sans anti-roll bar and cross-member which will go back on once the exhaust is in).

- Front hubs back together

Here's what's left for tomorrow:

- Install exhaust

- Fill with coolant (I don't have enough Blue coolant (barely) so need to head to the Stealer tomorrow)

- Put rear tires on and drop rear end so I can tighten crank nut (I have a huge note on the dashboard so I don't make the same mistake I made with Vlad on this one).

- Install fan

- Do static break-in

I got on the phone with the machinist/engine builder and got refreshed on his advised procedure:

- Immediately run it at 2200 rpm for 10 minutes

- Let it cool down (15-20 minutes)

- Another 2200 rpm run for 10 minutes

- Dump the break-in oil and put normal stuff in

- Get on the road and drive hard, avoiding idle as much as possible. Lots of < 5000rpm pulls. Hills are good. For the first 100 miles.

Question: What is the recommendation w.r.t. the ARP head bolts. When (at all?) should I pull the valve cover and re-torque?

The bolt on the idler arm ALMOST touches the headers. It's entirely likely that the motor moving around will impact steering. So if I DO go with the headers I'll have do to something about this.

I am delighted to report that I made huge progress.

- Driveshaft hooked up

- Heat shield in place

- Cooling system all hooked up

- Front suspension back together (sans anti-roll bar and cross-member which will go back on once the exhaust is in).

- Front hubs back together

Here's what's left for tomorrow:

- Install exhaust

- Fill with coolant (I don't have enough Blue coolant (barely) so need to head to the Stealer tomorrow)

- Put rear tires on and drop rear end so I can tighten crank nut (I have a huge note on the dashboard so I don't make the same mistake I made with Vlad on this one).

- Install fan

- Do static break-in

I got on the phone with the machinist/engine builder and got refreshed on his advised procedure:

- Immediately run it at 2200 rpm for 10 minutes

- Let it cool down (15-20 minutes)

- Another 2200 rpm run for 10 minutes

- Dump the break-in oil and put normal stuff in

- Get on the road and drive hard, avoiding idle as much as possible. Lots of < 5000rpm pulls. Hills are good. For the first 100 miles.

Question: What is the recommendation w.r.t. the ARP head bolts. When (at all?) should I pull the valve cover and re-torque?

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Win!

https://youtu.be/lqRKKVjvVqQ

Runs awesome. Did an extended shake down drive this evening after changing out the break-in oil. Pulls nice and hard, definitely more peppy than the old motor. Ooth and quiet. Of course I'm limiting to < 5000 rpm and I don't have a > 5000 rpm tach in the car yet. I was going to adjust the valves when I changed the oil but the valve train is silent. No leaks.

No idle issues. Perfect. I'm kinda blown away.

New suspension is so much better. The Billies with Spax are a great combo.

And the M5 steering box is TIGHT. LOVE.

On the down side, the clutch engagement point isn't noticably different after going to the shorter TO bearing. AND this transmission has developed the death rumble... Far worse than Vlad. I wonder if I screwed something up in the install. Could it be the TO bearing moving around?

https://youtu.be/lqRKKVjvVqQ

Runs awesome. Did an extended shake down drive this evening after changing out the break-in oil. Pulls nice and hard, definitely more peppy than the old motor. Ooth and quiet. Of course I'm limiting to < 5000 rpm and I don't have a > 5000 rpm tach in the car yet. I was going to adjust the valves when I changed the oil but the valve train is silent. No leaks.

No idle issues. Perfect. I'm kinda blown away.

New suspension is so much better. The Billies with Spax are a great combo.

And the M5 steering box is TIGHT. LOVE.

On the down side, the clutch engagement point isn't noticably different after going to the shorter TO bearing. AND this transmission has developed the death rumble... Far worse than Vlad. I wonder if I screwed something up in the install. Could it be the TO bearing moving around?

Last edited by tig on Jan 28, 2018 1:43 AM, edited 1 time in total.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

And I broke my hood release handle. Dammit.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

cek wrote:Win!

https://youtu.be/lqRKKVjvVqQ

Runs awesome. Did an extended shake down drive this evening after changing out the break-in oil. Pulls nice and hard, definitely more peppy than the old motor. Ooth and quiet. Of course I'm limiting to < 5000 rpm and I don't have a > 5000 rpm tach in the car yet. I was going to adjust the valves when I changed the oil but the valve train is silent. No leaks.

No idle issues. Perfect. I'm kinda blown away.

New suspension is so much better. The Billies with Spax are a great combo.

And the M5 steering box is TIGHT. LOVE.

Well done!

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Thanks Dave.

My buddy came over this morning and four hours later we got the transmission out, taller TO bearing in, and car back on the road. So much easier/faster wrenching with someone else (who's mechanically minded).

After a short drive, no more death rattle. Also clutch disengages at about the same place. Yay. Meh.

My buddy came over this morning and four hours later we got the transmission out, taller TO bearing in, and car back on the road. So much easier/faster wrenching with someone else (who's mechanically minded).

After a short drive, no more death rattle. Also clutch disengages at about the same place. Yay. Meh.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Rattle is still there. Rats. I guess this tranny just decided it was time. I checked fluid. Listened with stethoscope and it's clearly from further back than bell housing.cek wrote:Thanks Dave.

My buddy came over this morning and four hours later we got the transmission out, taller TO bearing in, and car back on the road. So much easier/faster wrenching with someone else (who's mechanically minded).

After a short drive, no more death rattle. Also clutch disengages at about the same place. Yay. Meh.

Total waste of time, but at least we know know both TO bearings work basically the same.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

I can't even.

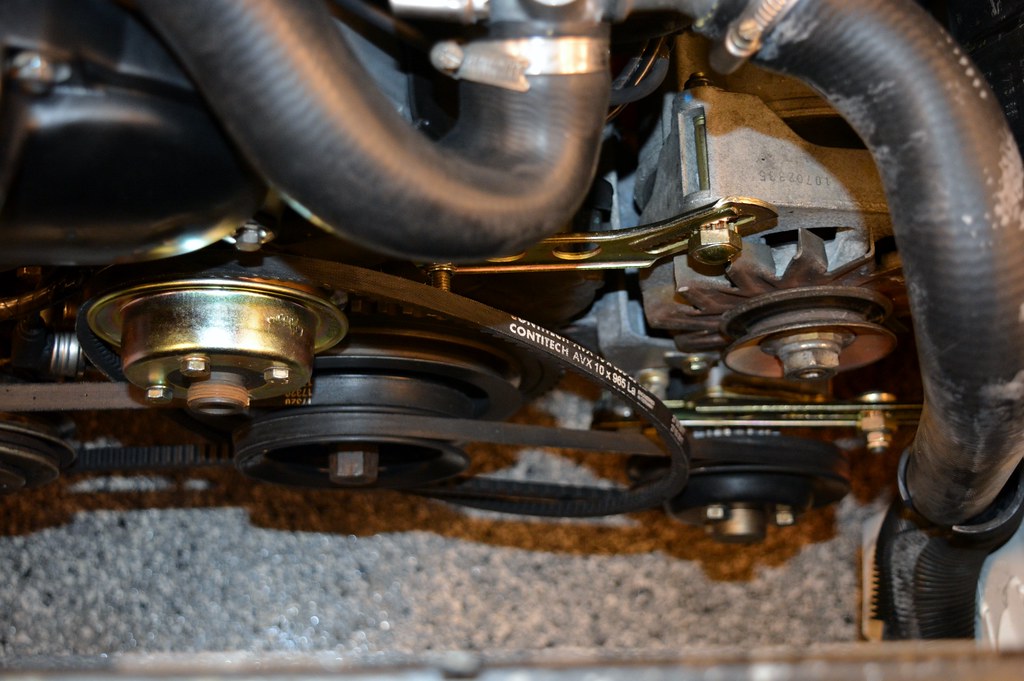

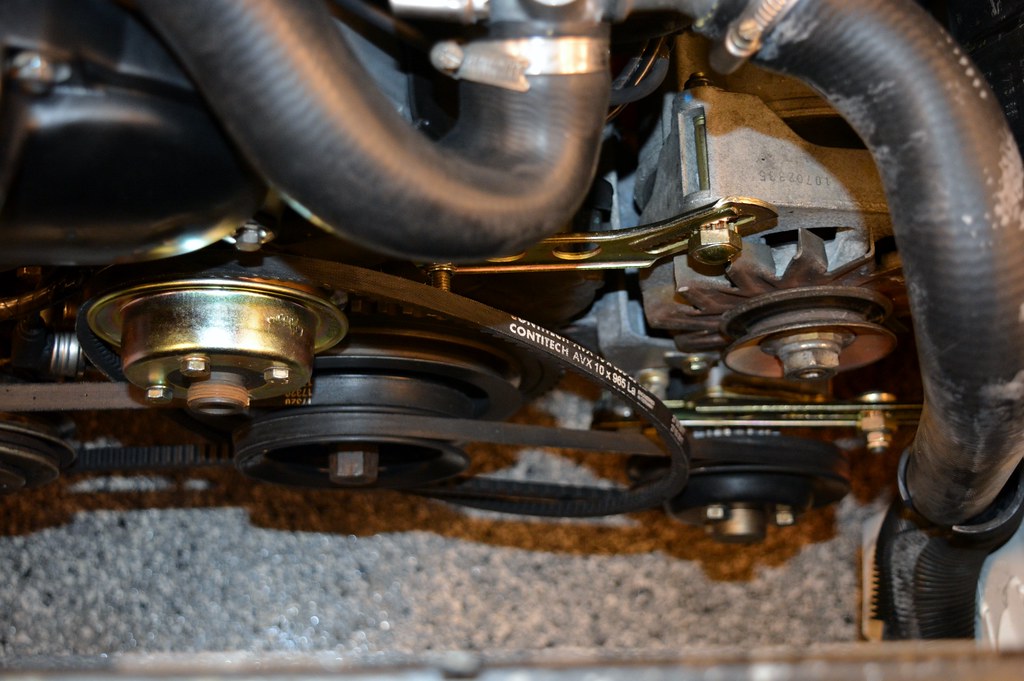

How does a water pump/alternator belt end up like this? Did it get caught by the other belts and sucked through them? This is the first time I've ever had a belt fail in anger on me (lucky, inexperienced, you choose).

Fortunately it happened right near home and I got home before it overheated.

The pully on the alternator looked a little wobbly. It was from a donor motor. I *knew* I should have just sprung for a rebuilt alternator, and stopped when I saw it wasn't straight, but I was trying to be somewhat frugal. That'll teach me.

How does a water pump/alternator belt end up like this? Did it get caught by the other belts and sucked through them? This is the first time I've ever had a belt fail in anger on me (lucky, inexperienced, you choose).

Fortunately it happened right near home and I got home before it overheated.

The pully on the alternator looked a little wobbly. It was from a donor motor. I *knew* I should have just sprung for a rebuilt alternator, and stopped when I saw it wasn't straight, but I was trying to be somewhat frugal. That'll teach me.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

It's is hurting my brain to imagine how it would be possible for the belt to be as you have shown.

Ask Penn & Teller ??

And I noticed your transmission has the red ATF Oil sticker on it. Maybe I misse dit but what oil did you put in it? IME ATF is too thin and they will work better hot and make less noise with a heavier oil like Redline MTL or even MT-90. Depends on the climate.

Ask Penn & Teller ??

And I noticed your transmission has the red ATF Oil sticker on it. Maybe I misse dit but what oil did you put in it? IME ATF is too thin and they will work better hot and make less noise with a heavier oil like Redline MTL or even MT-90. Depends on the climate.

Last edited by tn535i on Jan 29, 2018 1:39 PM, edited 1 time in total.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

I bet it isn't as lovely as an e36 R&P in an e30. But I do like the box in my M6 over the 535 for sure. It's interesting how slow steering boxes of any kind used to be and how big the steering wheels were. Now they (anything on there road it seems) are ALL faster and the wheels are smaller.cek wrote:And the M5 steering box is TIGHT. LOVE.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

I have MTL in it. I didn't even notice that sticker. I didn't put it there.tn535i wrote:It's is hurting my brain to imagine how it would be possible for the belt to be as you have shown.

Ask Penn & Teller ??

And I noticed your transmission has the red ATF Oil sticker on it. Maybe I misse dit but what oil did you put in it? IME ATF is too thin and they will work better hot and make less noise with a heavier oil like Redline MTL or even MT-90. Depends on the climate.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Well maybe it's pinkish. But I think that is the sticker they started putting on later transmissions that said "ATF Oil". I'll reiterate that IME even if it has the ATF Oil sticker... MTL is a better choice. I suppose you could try MT-90 to see if it reduces the gear noise... It did on my 88 M6 and even improved shifting, maybe a little stiffer cold but much better when hot.cek wrote:I have MTL in it. I didn't even notice that sticker. I didn't put it there.

-

delorean175

- Posts: 493

- Joined: Nov 16, 2009 5:36 PM

- Location: San Antonio TX

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

cek wrote:I now understand the shield wire thing, thanks. I also don't think the CTS or loom wire sensor were impacted.tn535i wrote:Shield wires should NOT have melted because as a shield it is only grounded at one end, the end you connected to the battery by mistake. So unless the shield wire was bare and touching something there should have been no current.

Something does not make sense to me when you describe the wires that cooked. Only things that could complete the circuit should have had current flow.

The CTS should have been open at the other end (No DME) so it should be OK. Same for the spark plug wire loom wire sensor and the coil.

The oil sensor is just a switch so the oil would have to be low and switch closed but that would send current somewhere I think. Maybe to other things connected to the check panel.

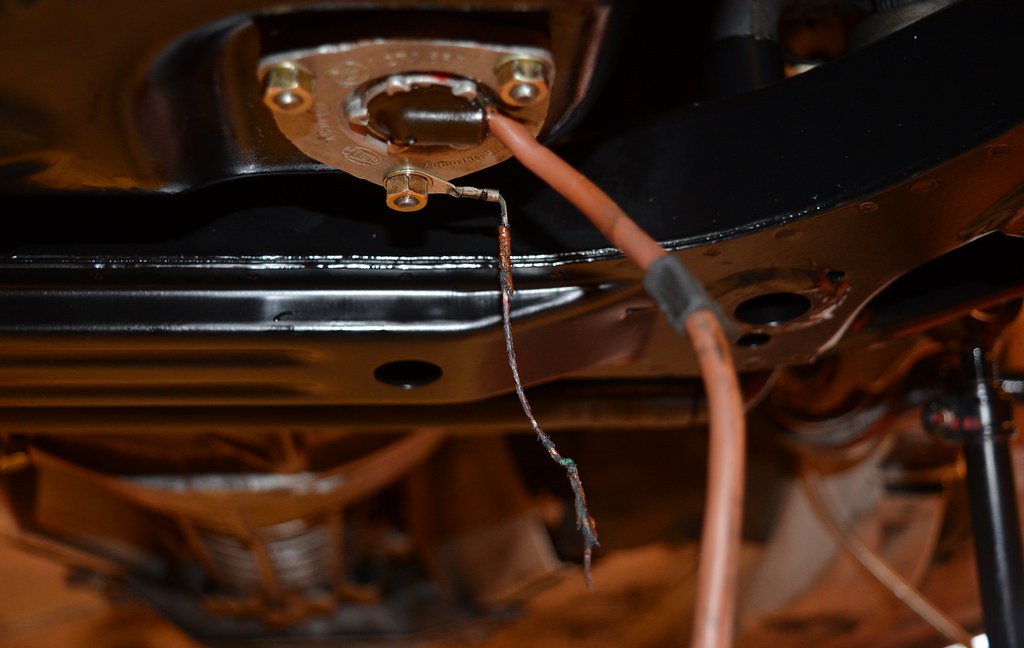

Here's the oil level sensor ground wire. It melted pretty far up into the harness; I've now pulled insulation all the way off to where it goes into the big bundle. FWIW, there's oil in there so the static switch (pin 1, BU/VI) is closed and the dynamic switch is open (Pin 2, BU/VI) [Page 6212-2].

The visible damage to the BR wire stops about where you see it in my hand.

No damage can be seen in any of the wires that go across the timing belt (Oil temp, coil).

If that were it, I'd actually think all I need to do was splice in a new ground wire for the oil level sensor...

HOWEVER, I'm seeing something I really don't understand:

I noticed continuity from the negative battery terminal to the GREEN coil wire. This is WITHOUT G103 connected. I also see continuity from ground to EVERY fuse connector as long as C101 is plugged in. Look at 1362-3 above and the GN coil wire (15) goes to fuse 6. If I remove fuse 6 I still see continuity (to (-) on battery) on BOTH sides of fuse.

The fact that this is INDEPENDENT of G103 (e.g. the ground from the wiring harness) is very confusing to me.

Am I thinking about this wrong, because this seems really odd? I think it means that somewhere some wires fused together which makes me very sad.

I feel your pain. During my first startup after my e2i swap I pinched the wires leading to injector no.5 in between the valve cover and head. When I torqued the bolts down it was tight enough to short out the positive and negative. When I attempted to start the engine I saw a puff of smoke followed by a burnt smell.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Ouch. Makes me feel better knowing others make similar mistakes.delorean175 wrote: I feel your pain. During my first startup after my e2i swap I pinched the wires leading to injector no.5 in between the valve cover and head. When I torqued the bolts down it was tight enough to short out the positive and negative. When I attempted to start the engine I saw a puff of smoke followed by a burnt smell.It took me a few hours to fish 2 new wires into the existing wiring harness, cut the burnt wires out, then solder and heat shrink everything and make it look nice like there was no accident. I really like your build, I admire your attention to detail.

BTW, do you realize how broken your signature is? Looks like this to everyone but you:

Please ditch photobucket, for the sake of humanity!

Back on topic...

I got back from my whirlwind trip to UK/NL this morning and dove into the alternator belt issue.

Here's what that Escher belt looks like. You can see how it was damaged winding its way under the other two belts.

I needed lunch and the Porsche needed some exercise as it's been sitting for a few weeks. So I drove to O'Riellys just to see if they had a reman'd 90A alternator. Sure enough they did. Only $83+core. I have three so giving up a core was no biggie. I pulled a straight pulley off one of the spares and installed the new/refubed unit.

No wobbly and I dare say a bit less belt noise. Went for a spirited test drive (with all tools required to fix the belt if it came off again) and no issues.

-

delorean175

- Posts: 493

- Joined: Nov 16, 2009 5:36 PM

- Location: San Antonio TX

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

I didn't know my signature was broken.cek wrote:delorean175 wrote: I feel your pain. During my first startup after my e2i swap I pinched the wires leading to injector no.5 in between the valve cover and head. When I torqued the bolts down it was tight enough to short out the positive and negative. When I attempted to start the engine I saw a puff of smoke followed by a burnt smell.It took me a few hours to fish 2 new wires into the existing wiring harness, cut the burnt wires out, then solder and heat shrink everything and make it look nice like there was no accident. I really like your build, I admire your attention to detail.

Ouch. Makes me feel better knowing others make similar mistakes.

BTW, do you realize how broken your signature is? Looks like this to everyone but you:

Please ditch photobucket, for the sake of humanity!

Anyway, I'm glad to see you got your belt situation figured out. I had to use nonfactory size belts to make everything work. I think for the later years of the m20 they changed pulley sizes around. I think they shrunk one and enlarged another because it shows the same size belts work for early and later engines. I think I have a mixture of old and newer pulleys so it requires a slightly larger belt. I ordered factory sized belts but the alternator belt wouldn't fit. I had a bit of customization to do to get the (early production) AC compressor to fit next to the motronic 1.3 CPS. They wouldn't clear each other. After it was all said and done it all looks factory and functions correctly. Your swap was probably a bit more straight forwards wasn't it?

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

See the thread linked in my signature, re: photos. Special note: Thoese Firefox/Chrome extensions are a sure way to ensure some kid in the Ukraine is seeing the entire contents of EVERY web page you visit.delorean175 wrote:I didn't know my signature was broken.cek wrote:delorean175 wrote: I feel your pain. During my first startup after my e2i swap I pinched the wires leading to injector no.5 in between the valve cover and head. When I torqued the bolts down it was tight enough to short out the positive and negative. When I attempted to start the engine I saw a puff of smoke followed by a burnt smell.It took me a few hours to fish 2 new wires into the existing wiring harness, cut the burnt wires out, then solder and heat shrink everything and make it look nice like there was no accident. I really like your build, I admire your attention to detail.

Ouch. Makes me feel better knowing others make similar mistakes.

BTW, do you realize how broken your signature is? Looks like this to everyone but you:

Please ditch photobucket, for the sake of humanity!Thank you for the heads up. What do you use instead of photobucket? I got a firefox extension called Photobucket hotlink. It fixes that problem so when I got to the older threads with a bunch of hotlinked photos from photobucket they display like they used to. I guess photobucket got greedy and wants you to pay for hotlinking or something like that. I'm not the most tech savy person but google is. lol

Anyway, I'm glad to see you got your belt situation figured out. I had to use nonfactory size belts to make everything work. I think for the later years of the m20 they changed pulley sizes around. I think they shrunk one and enlarged another because it shows the same size belts work for early and later engines. I think I have a mixture of old and newer pulleys so it requires a slightly larger belt. I ordered factory sized belts but the alternator belt wouldn't fit. I had a bit of customization to do to get the (early production) AC compressor to fit next to the motronic 1.3 CPS. They wouldn't clear each other. After it was all said and done it all looks factory and functions correctly. Your swap was probably a bit more straight forwards wasn't it?

It's a 10x965mm belt, as specified for this motor. Length-wise it fits perfectly (the adjuster can move ~2cm each way to tighten/loosen when the belt is at the correct tightness).

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

That's where I grab my Gates belts from.cek wrote:... O'Riellys...

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

FWIW, I compared this re-man 90A unit to the re-man 140A unit I just bought from autohausaz (for a ton more $), which is labeled Bosch.1st 5er wrote:

That's where I grab my Gates belts from.cek wrote:... O'Riellys...

The quality of the rebuild APPEARS about the same.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Be careful, with the O'Reilly's reman'd units...if that's what you have in there, that belt situation makes total sense to me: I went through TWO of their alternators that did this exact thing to me, kept constantly shredding belts, and it finally killed it's own bearings after about 10k miles. After the second shitty one, a forum member here felt sorry for me and sold me his "unknown condition" 528e alternator for the cost of a core and it's been working fine ever since without throwing a single belt (2+ years). Stay away from their batteries too, unless you like undiagnosable, intermittent, internal battery faultscek wrote:FWIW, I compared this re-man 90A unit to the re-man 140A unit I just bought from autohausaz (for a ton more $), which is labeled Bosch.1st 5er wrote:

That's where I grab my Gates belts from.cek wrote:... O'Riellys...

The quality of the rebuild APPEARS about the same.

-

delorean175

- Posts: 493

- Joined: Nov 16, 2009 5:36 PM

- Location: San Antonio TX

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Good to know, I'll remove that plugin right now. I'm making a Flicker account now. Thanks for the info on that, I'm ditching photobucket soon.delorean175 wrote:

See the thread linked in my signature, re: photos. Special note: Thoese Firefox/Chrome extensions are a sure way to ensure some kid in the Ukraine is seeing the entire contents of EVERY web page you visit.

It's a 10x965mm belt, as specified for this motor. Length-wise it fits perfectly (the adjuster can move ~2cm each way to tighten/loosen when the belt is at the correct tightness).

Re-manufactured 90A alternators, I have an Orileys reman unit in my car right now. It's my second one so far. I have a Bosch unit with bad bearings, I plan on replacing the bearings (with SKF brand bearings) and shelving it for the day my new re-manufactured unit dies. I wish they waren't to poor in quality but I guess its how it goes when you get desperate.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Exactly, the O'Reilly ones are crap. An alternator should last at least ten years on a BMW. >2/3 of the people on this forum are probably still running their original.delorean175 wrote:Re-manufactured 90A alternators, I have an Orileys reman unit in my car right now. It's my second one so far. I have a Bosch unit with bad bearings, I plan on replacing the bearings (with SKF brand bearings) and shelving it for the day my new re-manufactured unit dies. I wish they waren't to poor in quality but I guess its how it goes when you get desperate.

-

delorean175

- Posts: 493

- Joined: Nov 16, 2009 5:36 PM

- Location: San Antonio TX

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

I believe it, they are built to last. Lets see how long this O'Reillys alternator lastsduggi wrote:Exactly, the O'Reilly ones are crap. An alternator should last at least ten years on a BMW. >2/3 of the people on this forum are probably still running their original.delorean175 wrote:Re-manufactured 90A alternators, I have an Orileys reman unit in my car right now. It's my second one so far. I have a Bosch unit with bad bearings, I plan on replacing the bearings (with SKF brand bearings) and shelving it for the day my new re-manufactured unit dies. I wish they waren't to poor in quality but I guess its how it goes when you get desperate.

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

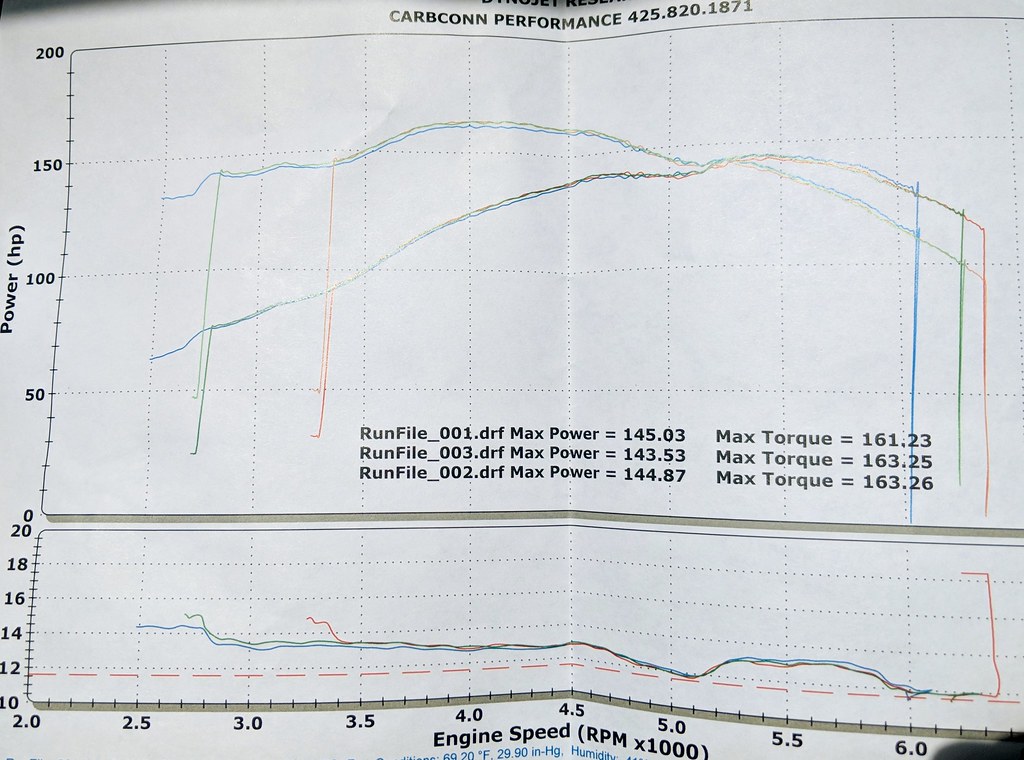

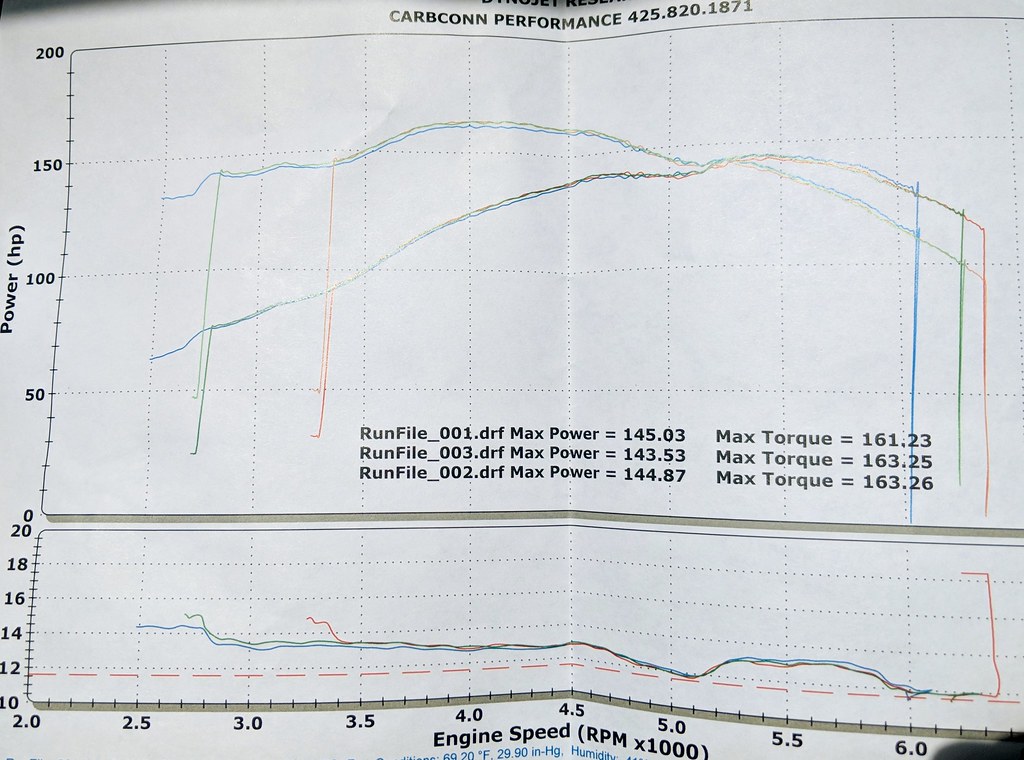

Documenting first dyno run with this engine:

https://www.youtube.com/watch?v=XVfYyjKU8XI

The results.

Lame. But not unexpected given the stock 325i tune and restrictive Eta exhaust (not even Super-Eta). The AFRs make it clear there's more in there. Glad to see no lean. Odd dip and rise at 5000rpm. Nice and flat curve.

When driving this car you definitely feel that low end torque between 3500-4500 rpm. Makes it a hoot to drive. This is motivating me to keep the exhaust a little restrictive...

Best of all it didn't esplode.

https://www.youtube.com/watch?v=XVfYyjKU8XI

The results.

Lame. But not unexpected given the stock 325i tune and restrictive Eta exhaust (not even Super-Eta). The AFRs make it clear there's more in there. Glad to see no lean. Odd dip and rise at 5000rpm. Nice and flat curve.

When driving this car you definitely feel that low end torque between 3500-4500 rpm. Makes it a hoot to drive. This is motivating me to keep the exhaust a little restrictive...

Best of all it didn't esplode.

-

Kyle in NO

- Posts: 17638

- Joined: Feb 12, 2006 12:00 PM

- Location: Nasty Orleans------> Batten-Rooehjch------>More Souther LA

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

Do the exhaust. You won’t lose any torque. Trust me.

-

delorean175

- Posts: 493

- Joined: Nov 16, 2009 5:36 PM

- Location: San Antonio TX

Re: Maytag's M20B27 'e2i' Engine Build Thread (87 528e)

This really intrigued by this because we have similar builds.cek wrote:Documenting first dyno run with this engine:

https://www.youtube.com/watch?v=XVfYyjKU8XI

The results.

Lame. But not unexpected given the stock 325i tune and restrictive Eta exhaust (not even Super-Eta). The AFRs make it clear there's more in there. Glad to see no lean. Odd dip and rise at 5000rpm. Nice and flat curve.

When driving this car you definitely feel that low end torque between 3500-4500 rpm. Makes it a hoot to drive. This is motivating me to keep the exhaust a little restrictive...

Best of all it didn't esplode.