Whew. That was a lot of work. I feel like I was rode hard and put away wet. Probably doesn't help that I played soccer for almost 2 hours this morning and then was so focused on wrenching I forgot to eat anything all day.

If you saw

this thread you know that I am struggling with the fact the clutch pedal disengages clutch too high and how to resolve. I learned a bunch (and discovered there are two variants of getrag 260/5; one with a 5mm deeper bell-housing). But I am still unsure why my engagement point is wrong. I'm moving ahead with what I think will address it: Switching to the shorter variant of the throw out bearing.

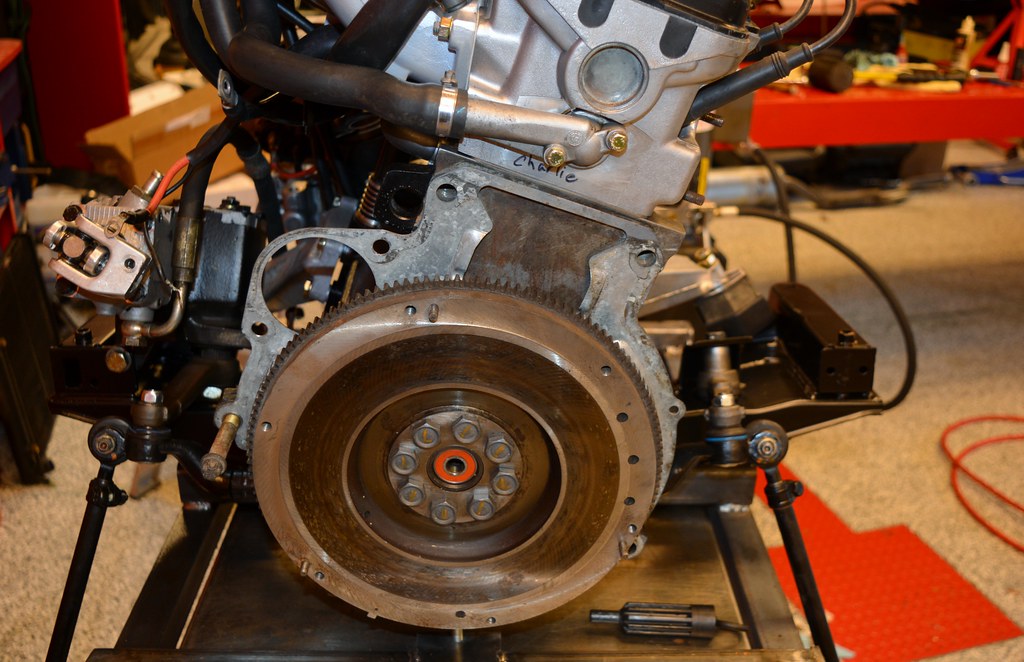

For future reference (for me when I forget and search this thread to remember), here's the specs on the transmission in this car:

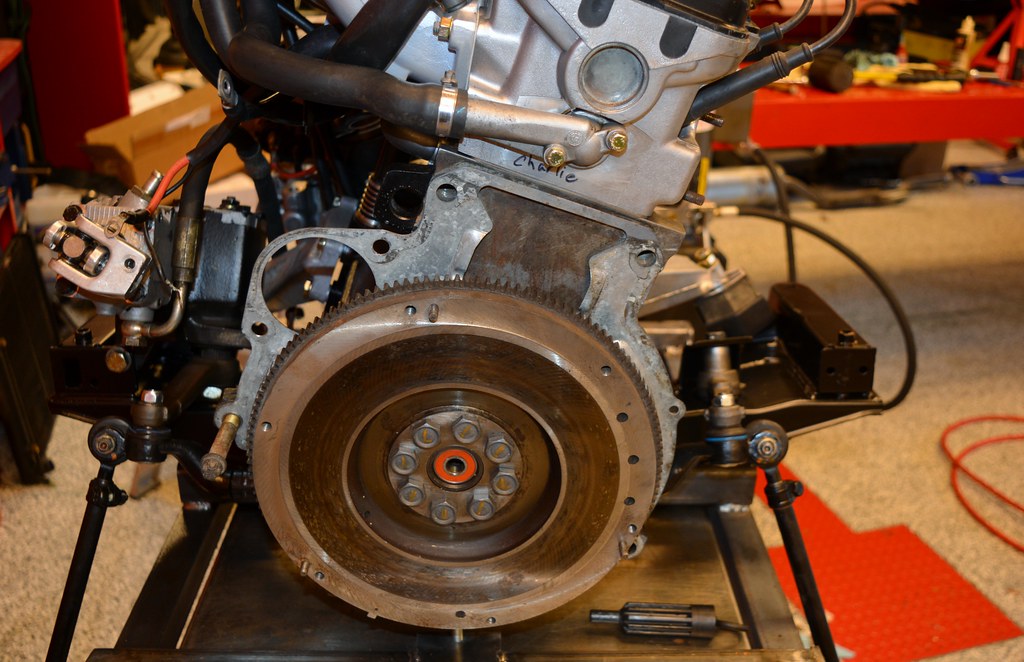

Transmission on Maytag

PN on Bellhousing: 260.0.1270.90

VIN: WBAAB5407H9696074

Model: 1986-07-31 US 325E (not a 528e as I had previously thought)

Housing PN from RealOEM: 23111222657

T/O Bearing PN from RealOEM: 21517521471

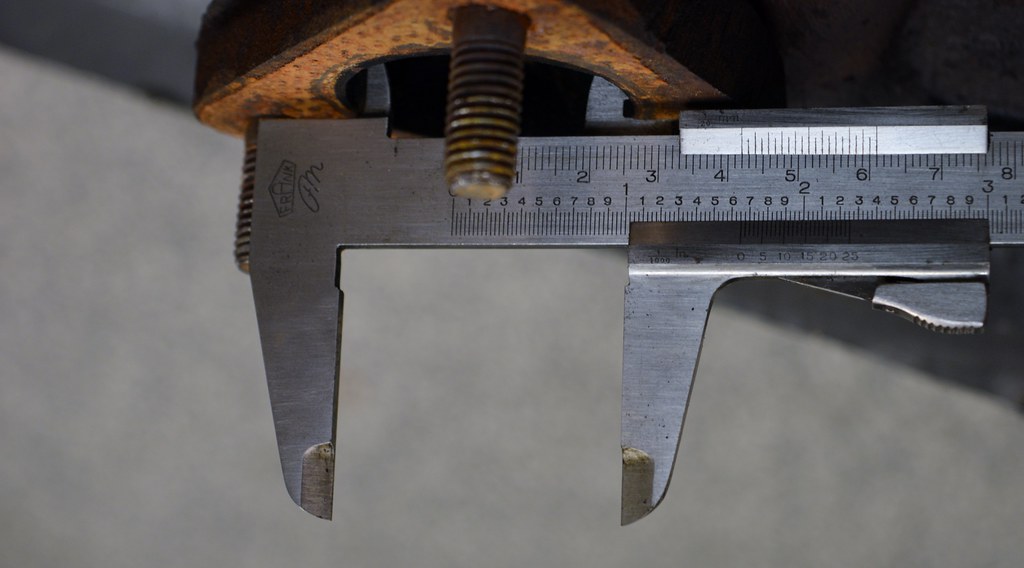

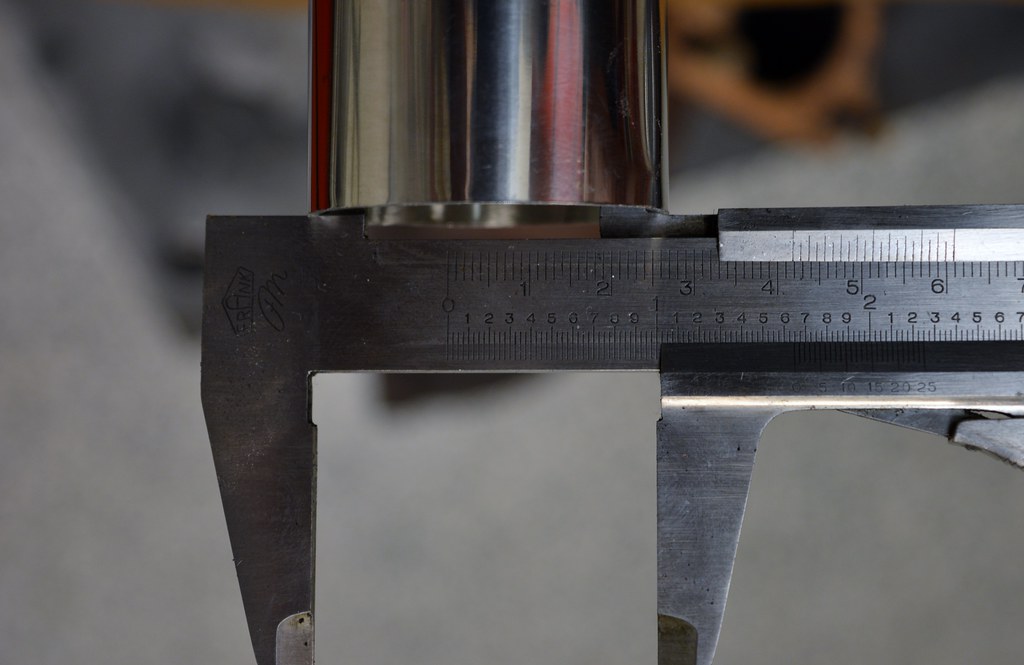

OAL (output shaft to bell-housing face): 55mm

Bell-housing length (rear casing front to bell-housing face): 37.5mm

Bell-housing depth (slave face to bell-housing face): 17mm

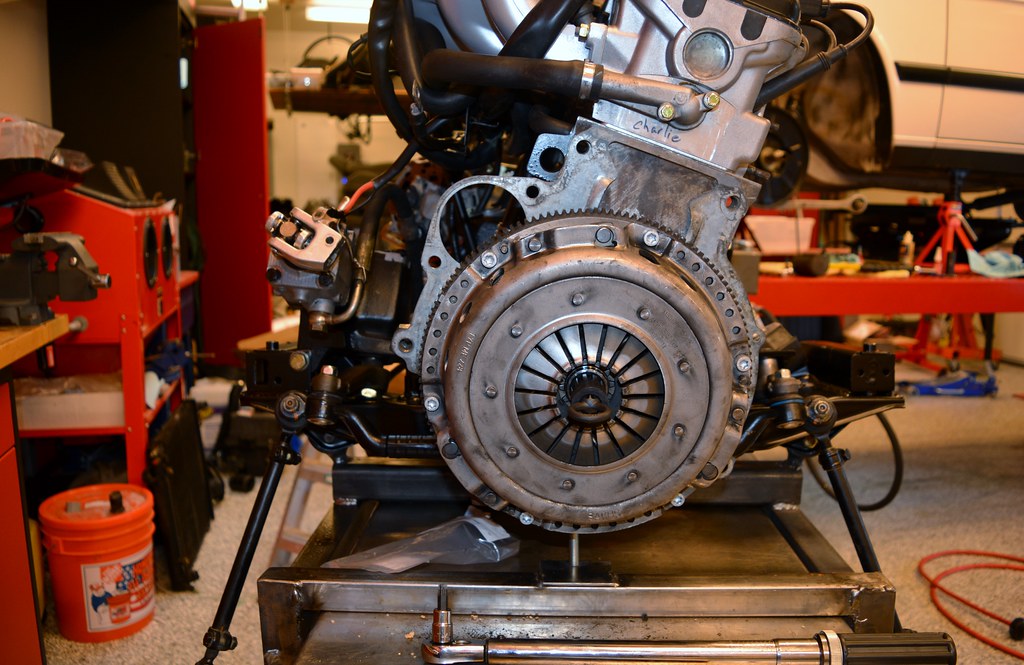

Got the right flywheel bolts from blunt.

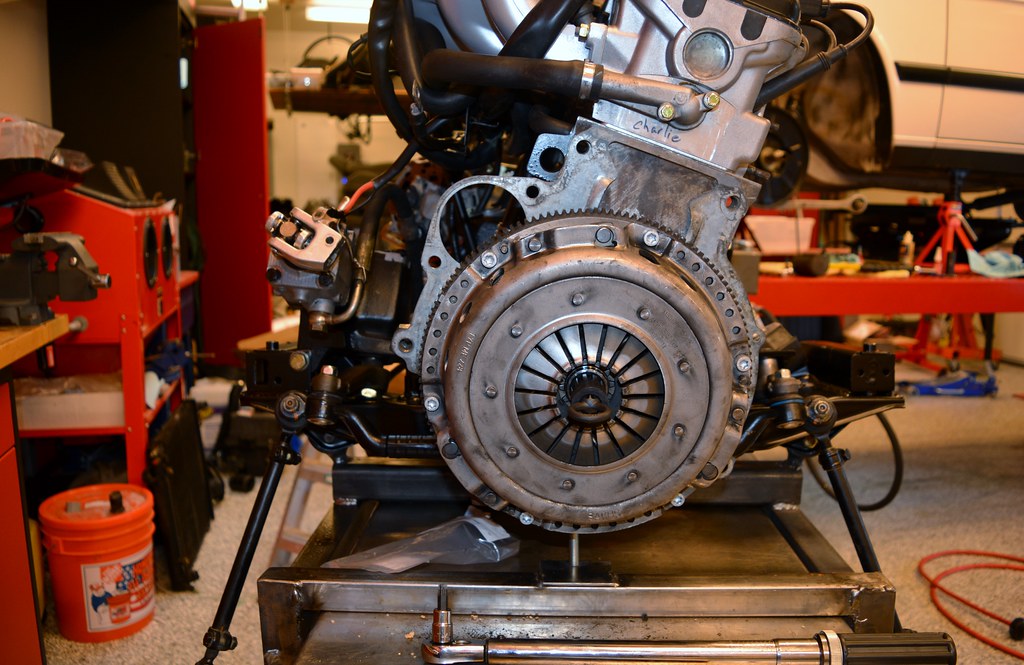

Hooked transmission up. Used the right greases on the splines and TO bearing.

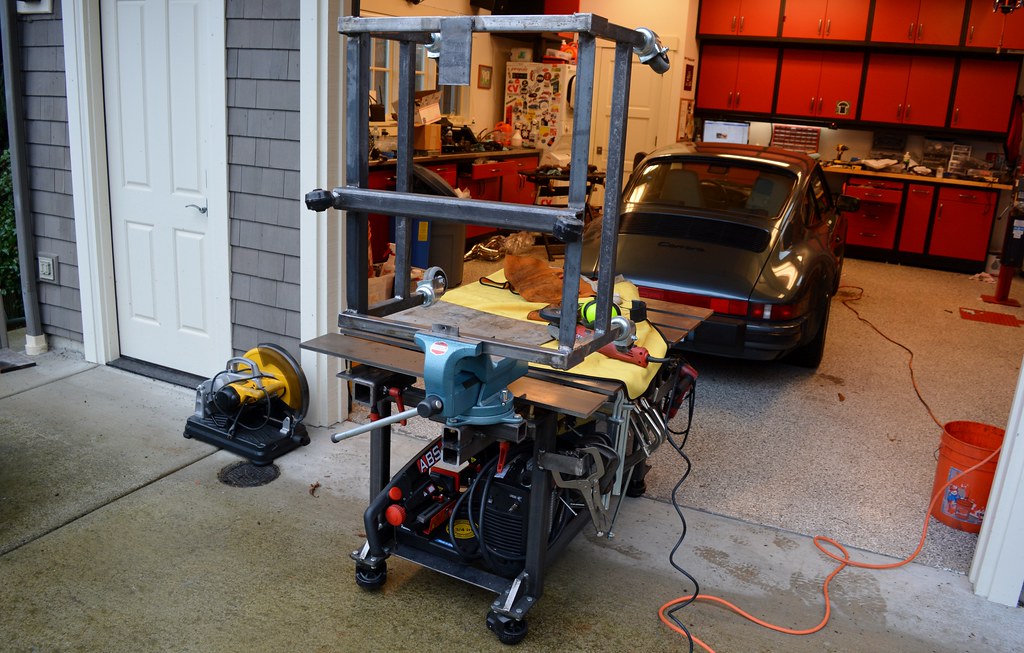

Tried another test-fitting lifting the engine and transmission up through the bottom with the lift table. Realized everything would go much more smoothly if I modified my cradle to mount the assembly further forward; will give more clearance with the front of my 4-post lift.

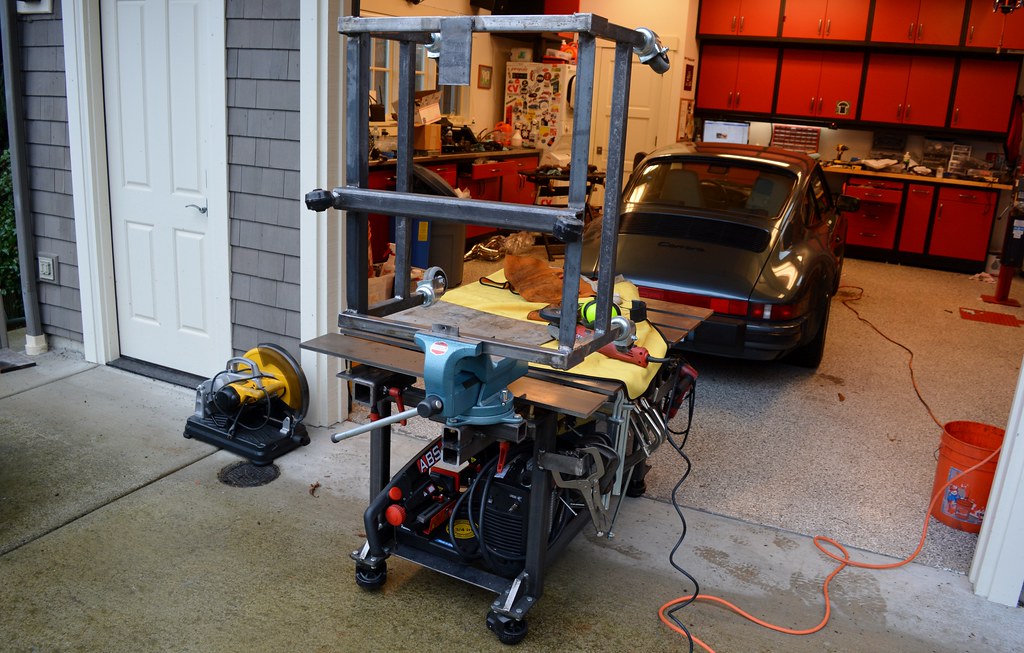

Always love a chance to get the welding table out!

A bit of the grinding wheel and some fresh welds and I set the engine/tranny back on. Much better balance too.

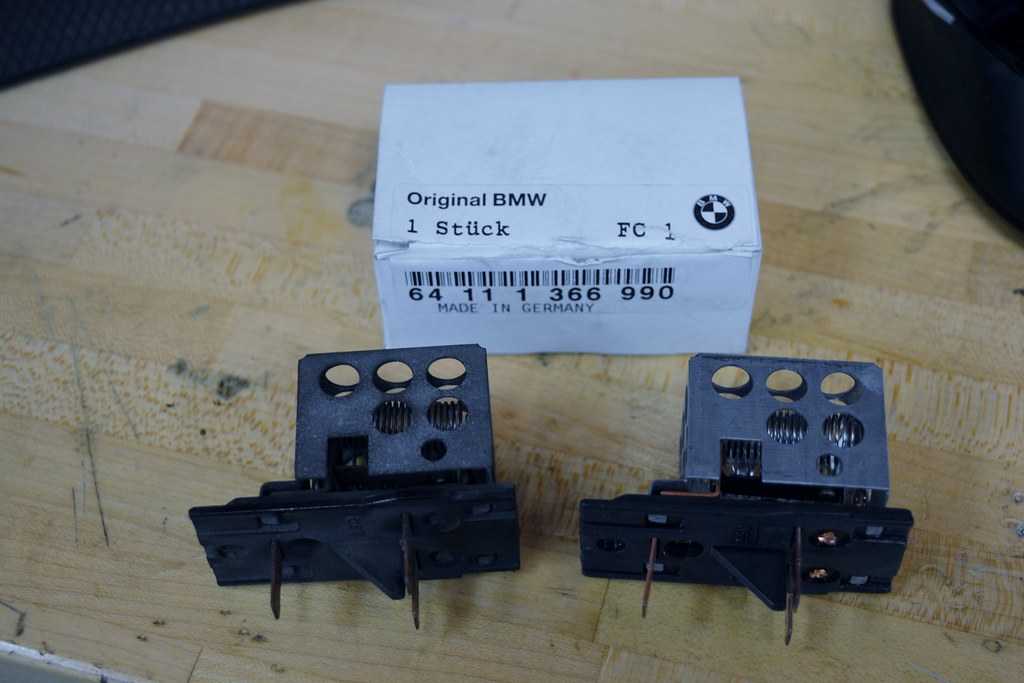

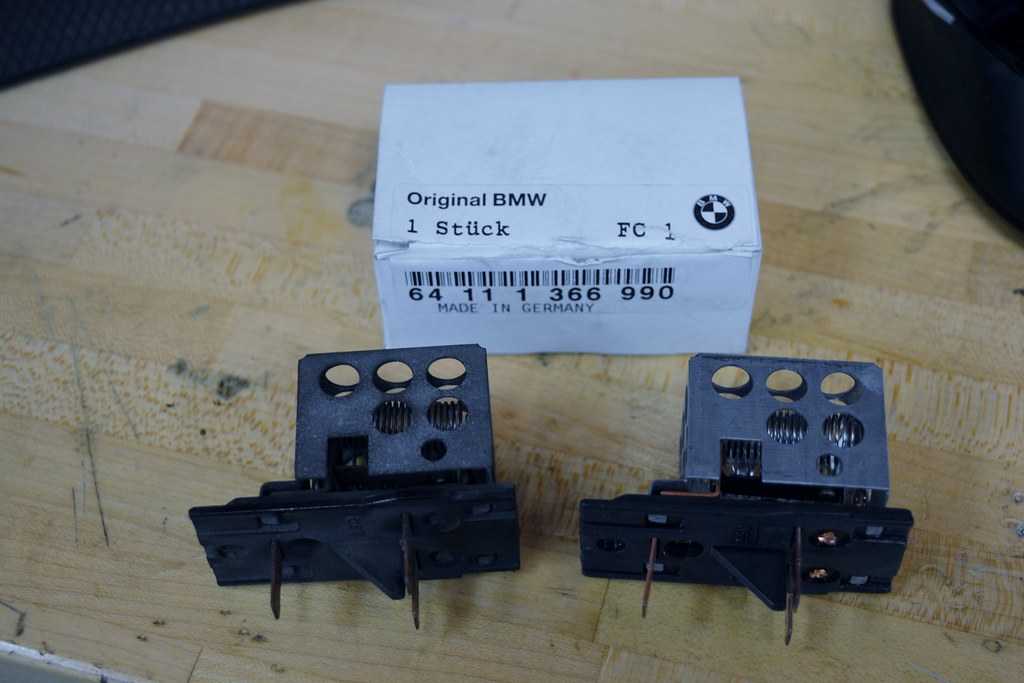

Got the starter installed and hooked up the PS hoses. Everything that needs to go together before it goes in the car is now done. But before I can put it in I need to do a few more things in the engine bay, including installing a new resistor pack. You'll recall my heater fan "races" to full speed at random times any time it is on. I expected the old resistor pack to look super rusty or destroyed. It actually looks fine. Hopefully this actually fixes the problem.