rebuilt m30b35

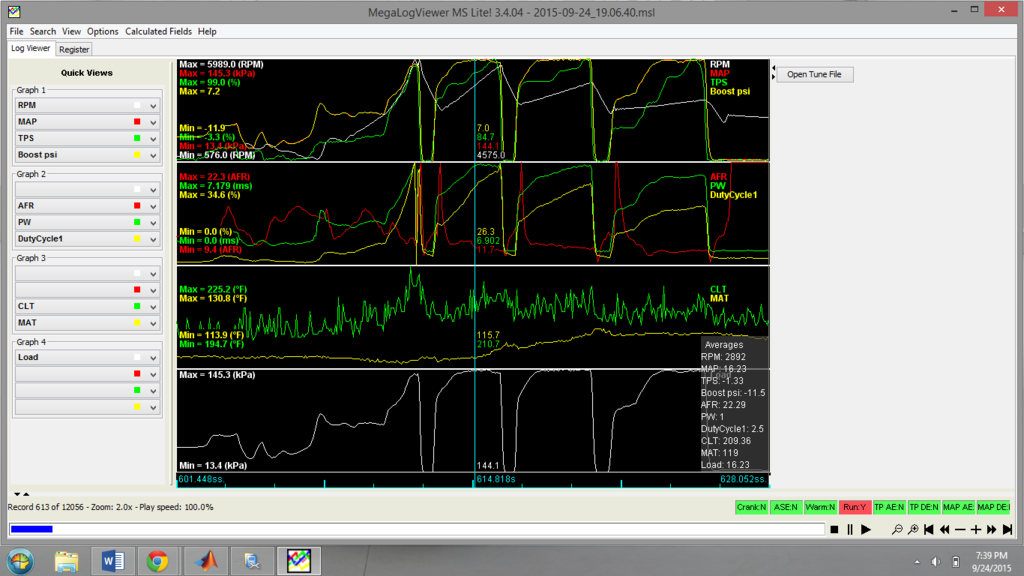

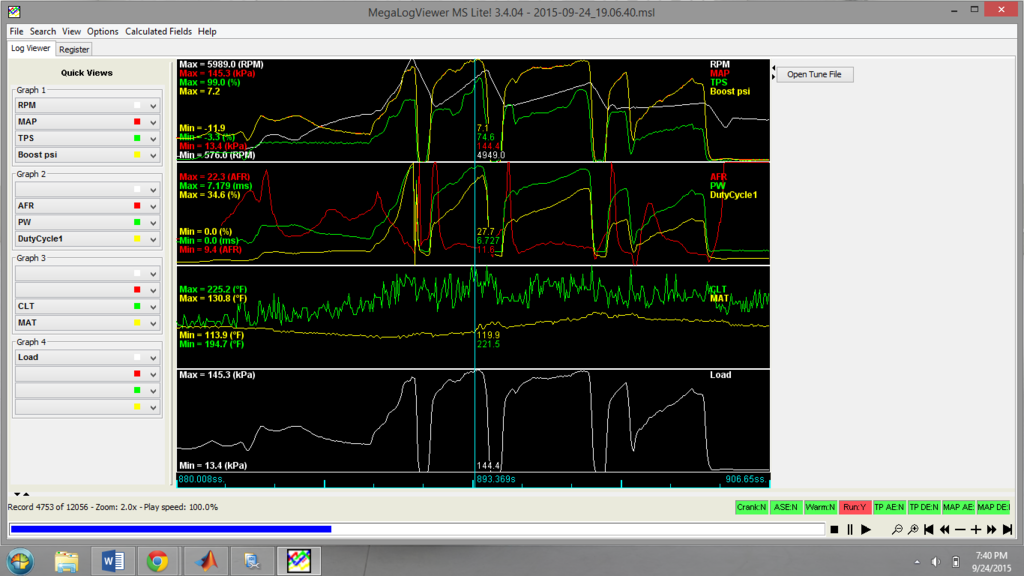

ms2 v3 with a lc2 wideband

m5 clutch/pressure plate

holset hx35, wanted an hx40 but couldnt pass this up for the price

80 lb deka injectors

35 mm tial wastegate

bosch bpv

-12 an oil drain for the holset

1/4 hardline for oil feed

3 inch steel exhaust

free intercooler that i think is to small. i ditched the valance and will just run my is bumper cover. I only had to spot weld a few brackets to eliminate it.

Everything that i could mig weld i did, i couldnt imagine trying to tig all that. I tig welded all the aluminum bungs plus the stainless transition cone the goes from 2.5 to 3. The wategate has a 9.5 psi spring so well see how that does, all the tube for that is .120 wall. I used vbands for every connection that i could just to make assembly easier. I plan on using the stock icv so i left that in the stock location. The oil feed was made using steel 1/4 tubing. my dad has a fancy hydualic flaring tool to make an flares so i figured why not. It was easy to bend and goes from the oil filter housing under the oil pan tucked along the subframe and then up to the turbo. Inline i plumbed a vdo oil pressure sensor. The map sensor and boost gauge are both tapped into the intake, 1/4 npt. The intercooler is made up of pieces i could find off craigslist. I know the iat sensor is too close and needs to be reloceted, i figured that out after i installed it.

Heres some things i discovered along the way, first no one makes a -12an drainflange for a reasonable price, i used some 1/4 in aluminum and tiged it to a male -AN fitting. I had some triangular flanges plasmacut out of 3/8 steel then i found out i should've cut them from stainless, Why? Turns out stainless buttweld pipe is half the price of mild steel. yay china. Anyway heres some pics of whats been done, i still need to drill the return to the pan and finish my gauges.

I do have a few questions though, first where is the best place to plumb the bpv, does it have to be as close to the tb as possible of can i have it anywhere. Also i can just vent that ti the stmospher right? it doesnt have to be plumbed back in. Second do i really need a better solution than just venting to the atmosphere with crank case vent? I know slight vaccum in the crank case is beneficial but i dont think it will make that much of a difference under boost.